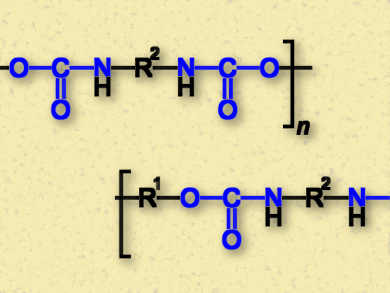

80 years ago, Otto Bayer discovered polyurethane chemistry by accident. Polyurethane has become one of the world’s most versatile polymers. The polymer has virtually changed the world. It is used for insulation panels (e.g. for refrigerators), upholstered furniture, car seats, coatings and lightweight composites, rotor blades for wind turbines, soccer balls, etc.

Otto Bayer (1902–1982) studied chemistry and received his Ph.D. from the University of Frankfurt am Main, Germany, in 1924 under the supervison of Julius von Braun. As head of a research group at IG Farben, Leverkusen, Germany, he discovered the polyaddition for the synthesis of polyurethane out of poly-isocyanates and polyols in 1937. The German patent was published on Novermber 13, 1937 [1].

Later he discovered a direct synthesis of polyacrylnitrile from acrylonitrile [2]. In 1944, Bayer became Professor of Chemistry at the Technology University of Cologne, Germany. He also was a Member of the Supervisory Board of Bayer, Leverkusen, Germany. Otto Bayer was not related to Friedrich Bayer, the founder of the Bayer corporation. For his work in the field of technical polymer synthesis and for the development of new technical materials (polyurethanes), he received the Werner-von-Siemens-Ring in 1960 together with Walter Reppe and Karl Ziegler.

Covestro, Leverkusen, recently has developed a method for using CO2 to synthesize polyols as polyurethane building blocks [3]. The company markets these raw materials under the brand name cardyon™ for the production of flexible polyurethane foam. Covestro also operates a new production plant for polyols at its Dormagen site near Cologne, Germany. According to Covestro, up to 20 % of the fossil raw materials previously used in these products have been replaced by CO2. A special catalyst gives the molecule the required level of reactivity.

Since 2015, a pilot plant of BASF produces the extra slim and efficient insulation material SlentiteTM in operation in Lemförde, Germany [4]. The polyurethane-aerogel insulating panels show very high insulation rating at minimal space requirements.

References

[1] I.G. Farben (Otto Bayer, Werner Siefken, Heinrich Rinke, L. Orthner, H. Schild), German Patent DRP 728981, A process for the production of polyurethanes and polyureas, 1937.

[2] Otto Bayer, Das Di-Isocyanat-Polyadditionsverfahren (Polyurethane), Angew. Chem. 1947, 59, 257–272. https://doi.org/10.1002/ange.19470590901

[3] CO2 Instead of Crude Oil, ChemistryViews.org 18 June 2016.

[4] Vera Koester, Marc Fricke, Insulation Through an Organic Polyurethane-Based Aerogel, ChemViews Mag. 2014. https://doi.org/10.1002/chemv.201400093