Heterogeneous catalysis relies on supports that provide a large surface area for the loading of an active phase. The identification of titanium oxide as not only a catalyst but also a support has opened up a new perspective on semiconductor materials.

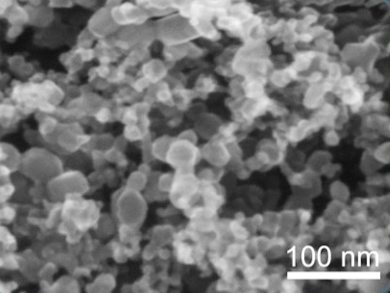

Xiaobing Zhu and Ai-Min Zhu, Dalian University of Technology, China, and colleagues have developed a plasmochemical synthetic strategy for the template‐free and one‐step preparation of highly crystalline mesoporous TiO2 from the oxidation of titanium tetraisopropoxide (TTIP) aerosol by gliding arc plasma in a vortex air flow within milliseconds.In traditional template-based methods, a calcination step is required to remove the template, which can shrink the pores and cause agglomeration of particles. This synthesis uses an aerosolized precursor method instead. A reverse vortex air flow provides an inward confined force. Gaseous products are formed and generate an outward force. A tunable force balance in the aerosol phase allows the formation of the wormhole‐like mesoporous TiO2 structures without the use of templates.

The highly crystalline mesoporous TiO2 has an optimized anatase/rutile weight ratio of about 80/20 for photocatalytic applications, shows superior thermal stability and good photocatalytic activity. According to the researchers, their method can readily replace current methods and it avoids solvent-related processes, reduces waste, and improves efficiency. In addition, the template-free nature of their synthesis prevents the collapse of the porous structure that can occur during calcination.

“The next step is to control the pore size and pore wall with optimal configuration of the plasma reactor and synthetic conditions, and to minimize the residual carbonaceous species, whereby better activity should be achieved”, Ai-Min told ChemViews Magazine.

- Plasmochemical approach to template-free synthesis of highly crystalline mesoporous TiO2 within milliseconds,

Si-Yuan Zhang, Xiao-Song Li, Jing-Lin Liu, Xiaobing Zhu, Ai-Min Zhu,

ChemNanoMat 2018.

https://doi.org/10.1002/cnma.201800574