Modern portable electronics predominantly use lithium-ion batteries. Larger displays and higher computing power, for example, in smartphones, cause a need for batteries with ever higher capacities. Anode materials with high theoretical capacities, however, often suffer mechanical damage from the large volume changes when lithium is incorporated into the material and then released again. This limits their practical use.

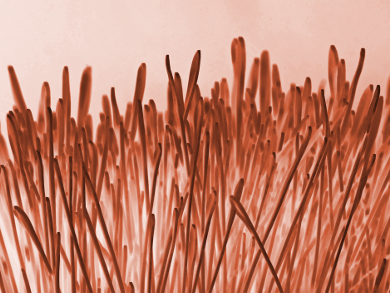

Giovanni B. Appetecchi, Italian National Agency for New Technology, Energy and Sustainable Economic Development (ENEA), Rome, and colleagues have tested germanium and silicon nanowires as improved anode materials for lithium-ion batteries. The team used diphenylgermane or phenylsilane as precursors to grow the respective nanowires on either a copper or tin substrate. The nanowire-covered foils were used as electrodes together with an ionic liquid electrolyte to build battery half-cells. The electrolyte was based on N-methyl-N-propylpyrrolidinium bis-(trifluoromethanesulfonyl)imide and N-methyl-N-propylpyrrolidinium bis(fluorosulfonyl)imide.

The researchers found that the electrodes had initial capacities of 1400 mAh g−1 for germanium and 2200 mAh g−1 for silicon. During repeated charging/discharging cycles, the nanowires are restructured to form a porous network. The network provides enough space for the uptake of lithium and is thus resistant to the volume changes that come along with it. This leads to a capacity retention of 50 % for silicon anodes after 500 cycles and 67 % for germanium anodes after 1000 cycles. According to the team, the combination of ionic liquid electrolytes and nanostructured electrodes could lead to safer lithium-ion batteries with high power densities.

- Behavior of Germanium and Silicon Nanowire Anodes with Ionic Liquid Electrolytes,

Guk-Tae Kim, Tadhg Kennedy, Michael Brandon, Hugh Geaney, Kevin M. Ryan, Stefano Passerini, Giovanni B. Appetecchi,

ACS Nano 2017.

DOI: 10.1021/acsnano.7b01705