Elastic polymers such as silicone have been used in medical devices for decades. They are, however, prone to the accumulation of proteins and bacteria (called biofouling) on their hydrophobic surface. This can lead to infections and other complications. To solve this problem, the materials can be coated with nonfouling materials such as zwitterionic polymers. These make the surface hydrophilic enough to bind a protective water layer that prevents biofouling. However, the coating process can be difficult and fail to deliver a high nonfouling activity that is stable in the long term.

Shaoyi Jiang, University of Washington, Seattle, USA, and colleagues have developed a coating-free nonfouling elastomer. The approach is based on the zwitterionic polymer polycarboxybetaine (PCB). The team “hid” this polymer’s charged quaternary amine groups by converting them into uncharged tertiary amines and the charged carboxylate groups by converting them to neutral esters. The result is a tertiary carboxybetaine ester polymer (PTCBE). This material has mechanical properties that are suitable for use in medical devices.

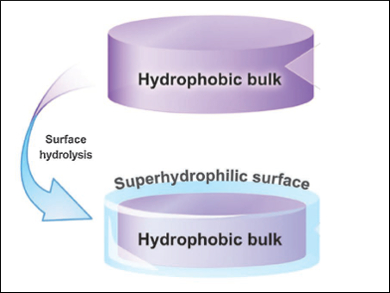

After polymerization, the surface of PTCBE can be hydrolyzed using an NaOH solution at 50°C. The amines are protonated and the esters are converted to carboxylate groups during this process. This renders the resulting zwitterionic surface superhydrophilic and nonfouling, while the bulk of the material retains its properties (pictured). The team used human serum at temperatures of 37 °C to test the material’s stability under physiological conditions. They found that the polymer’s properties were unchanged after a period of 60 days. The material is also noncytotoxic and, according to the researchers, is promising for biomedical and engineering applications.

- A Coating-Free Nonfouling Polymeric Elastomer,

Hsiang-Chieh Hung, Priyesh Jain, Peng Zhang, Fang Sun, Andrew Sinclair, Tao Bai, Bowen Li, Kan Wu, Caroline Tsao, Erik J. Liu, Harihara S. Sundaram, Xiaojie Lin, Payam Farahani, Timothy Fujihara, Shaoyi Jiang,

Adv. Mater. 2017.

DOI: 10.1002/adma.201700617