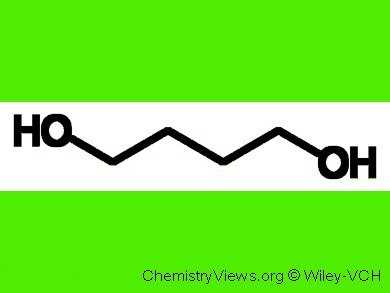

BASF plans to begin production of 1,4-butanediol (BDO) based on renewable feedstock using the patented process of Genomatica, San Diego, California. The one-step fermentation process is based on sugars as a renewable feedstock.

The license agreement allows BASF to build a world-scale production facility that will use the Genomatica process and Genomatica to continue to advance its patented renewable BDO production process technology based on sugars. The renewable BDO will be available in the second half of 2013 for sampling and trials.

BDO and its derivatives are widely used for producing plastics, solvents, electronic chemicals and elastic fibers. The starting materials for the production of conventional BDO are natural gas, butane, butadiene, and propylene. BASF currently produces BDO and BDO-equivalents at its sites in Ludwigshafen, Germany; Geismar, Louisiana, USA; Chiba, Japan; Kuantan, Malaysia; and Caojing, China, and has an annual capacity of 535,000 metric tons. The company has recently announced the intention of building a BDO complex in China with a capacity of 100,000 annual metric tons.

- BASF SE, Ludwigshafen, Germany