Most silks produced by spiders to make their webs have exceptional mechanical properties. To explore these, such fibers and films typically are not obtained from spider silks but from mulberry silkworm threads. The main drawback of reconstituted silk-based fibers is their material properties, which compare unfavorably with those of native silk threads unless they receive considerable un-biological post-draw treatments. Until now there were no examples of native silk films naturally extruded through an evolved production system, so there was no possibility of estimating the inherent mechanical properties possible for such films.

Hannes C. Schniepp, The College of William & Mary, Williamsburg, VA, USA, and colleagues examined the film ribbons spun by the brown recluse spider Loxosceles laeta. They managed to extract silk fibers directly from the spider and manipulated the ribbon parameters via controlling the spinning conditions and by this were able to perform sophisticated experiments with the materials, such as contacting the fiber with other materials or devices in a controlled manner.

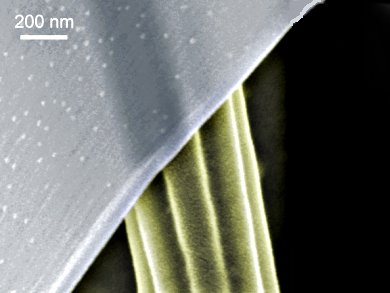

Scanning electron microscropy revealed that the fiber is a thin, flat ribbon of uniform width. The ribbons can easily bend and wrinkle, since they are extremely thin. Atomic force microscopy (AFM) revealed that the ribbons are 40–80 nm thick with widths in the range of 6–9 μm. Dimensional fluctuations between fibers from a particular animal taken at different times are significantly less than the fluctuations between fibers from different animals. Narrower fibers are consistently thinner than wider fibers; the cross-sectional aspect ratios of all fibers measured were in the range 1:100–1:150.

The team thinks that the naturally spun ribbon of Loxosceles silk – a unique hybrid of fiber and film, of orthodoxy and novelty – is likely to inspire the next generation of artificial silk films.

- Brown Recluse Spider’s Nanometer Scale Ribbons of Stiff Extensible Silk,

Hannes C. Schniepp, Sean R. Koebley, Fritz Vollrath,

Adv. Mat. 2013.

DOI: 10.1002/adma.201302740