A Sustainable Biomass Resource

Wheat straw is a widespread agricultural waste product in the breadbasket nations of the world. A fraction of the dry stalks of cereal plants left behind after the grain is harvested are used for animal bedding and other relatively small-scale applications. However, wheat straw is also a sustainable biomass resource which can be converted to various derivatives. A team from the U.S. and China have devised a way to directly convert wheat straw into electricity using a suitable fuel cell.

Yulin Deng, Georgia Institute of Technology, Atlanta, USA, and colleagues explain that biomass is the most common renewable energy form. They point out that research has focused on the development of low-cost, efficient, and effective methods for converting biological waste products from agriculture, the food industry and elsewhere into energy-rich fuels. Usually, the products are combusted for heating, transport, or conventional electricity generation.

Cleaner Conversion

An alternative approach might be to use the biomass to drive an electricity-generating fuel cell instead of burning it to drive generator turbines. Such an approach would have the advantage of extracting more energy more efficiently and produce less pollution – no sulfur oxides and no particulate emission (such as PM2.5) – while simultaneously making use of a widespread waste product.

Writing in the journal ChemSusChem, the team points out that, in addition to efficiency and lower pollution, the development of small-scale biomass-driven fuel cells would preclude the need for transporting the biomass to central generating facilities. Instead, local fuel cells might be biomass powered and provide adequate electricity to supply the farm itself and perhaps local residents without recourse to extensive new infrastructure.

Biomass-Based Fuel Cells

There are two well-known fuel cells: solid oxide fuel cells (SOFCs) and microbial fuel cells (MFCs) for converting biomass to electricity. The chemical energy of the biomass is converted into electrical energy as it drives oxidation at the anode and oxygen reduction at the cathode in both systems. Unfortunately, to use biomass-based SOFCs, the biomass must be converted to a gas, which requires burning biomass between 600 and 1000 °C. In the case of MFCs, the microbes can act on the biomass at room temperature, but they cannot process lignocellulosic biomass, such as that obtained from straw, without extensive pre-treatment.

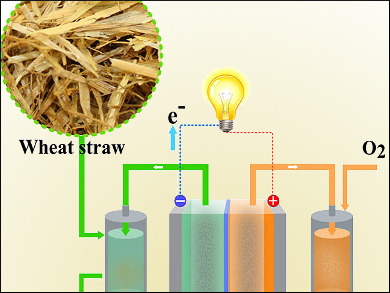

The team had previously reported a new type of flow fuel cell that can oxidize biomass directly to generate electricity at low temperature (less than 100 °C). This design uses two different liquid catalysts, based on iron(III) and vanadium(IV), in the anode and the cathode, respectively. The researchers have now developed this setup further to work with wheat straw biomass by employing an aqueous iron(III) oxidant to degrade the biomass at the anode and a simple and readily available vanadium(IV)/vanadium(V) couple with nitric acid-oxygen redox system at the cathode.

This system takes in finely powdered wheat straw, which is first oxidized by the iron ions in the anode tank at approximately 100 °C. The resulting reduced iron(II) is oxidized by vanadium in the cathode. The vanadium species is completely regenerated by oxygen. All the while, the system generates electricity at a rate of 100 mW/cm2. Importantly, the approach avoids the need for expensive noble metal catalysts.

Low-Cost Electricity from Waste

In principle, this flow fuel cell could be easily adapted to work with other forms of biomass, such as rice straw, grass, or even wood powder for clean electricity generation. The team is now expanding the biomass sources they might use from wheat straw to waste materials, such as lignin from paper mills, biowaste from daily life, sludge from petroleum production, and so on. They are also working on further improving the power density and the scale-up of the technology. “The energy balance indicates that the biomass flow fuel cell has practical application potential for the conversion of many types of biomass, such as agricultural waste, woods, grasses, to electricity,” the team concludes.

Junyong Zhu of the US Forest Service R&D, Forest Products Laboratory, in Madison, Wisconsin, agrees that direct biomass fuel cell is a new technology that offers great potential for low-cost electricity production. He points out that while MFCs have attracted a lot of interest over the last two decades, there have been huge barriers to their commercial success because getting sugars from biomass is itself very costly. “Using low-cost catalysts to directly convert biomass to electricity is a substantial advance in the development of fuel-cell technology,” Zhu says.

- Direct Conversion of Wheat Straw into Electricity with a Biomass Flow Fuel Cell Mediated by Two Redox Ion Pairs,

Jian Gong, Wei Liu, Xu Du, Congmin Liu, Zhe Zhang, Feifei Sun, Le Yang, Dong Xu, Hua Guo, Yulin Deng,

ChemSusChem 2016.

DOI: 10.1002/cssc.201601441