Biodiesel, an alternative to conventional diesel fuel, is produced by a reaction of triglycerides (from vegetable oil or animal fat) with alcohol (EtOH or MeOH). Although the use of ethanol as sustainable alcohol is increasingly gaining attention, the separation of the biodiesel from the glyceridic side products is quite costly and requires high amounts of washing water.

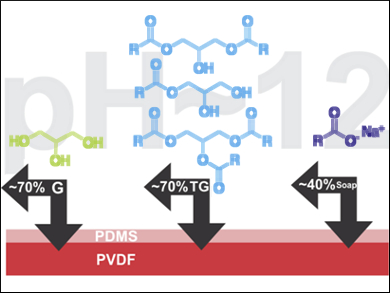

Cecilia Pagliero, Universidad Nacional de Río Cuarto, Argentina, and colleagues have used composite nanofiltration membranes to purify biodiesel produced by reacting soybean oil with bioethanol. The membranes are made from poly(vinylidene difluoride) with a coating layer of poly(dimethylsiloxane) using a phase inversion process.

The membranes are highly stable under harsh conditions such as increased pH and high temperatures. They also have a high retention rate for glycerol, glycerides, and soap components from the biodiesel even after multiple cycles of use. They could reduce the operating and capital costs of biodiesel purification, while mitigating the environmental impact by decreasing the amount of waste washing fluids.

- Biodiesel Purification Using Polymeric Nanofiltration Composite Membranes Highly Resistant to Harsh Conditions,

Juan J. Torres, Javier Toledo Arana, Nelio A. Ochoa, José Marchese, Cecilia Pagliero,

Chem. Eng. Technol. 2018, 41, 253–260.

https://doi.org/10.1002/ceat.201600257This article is part of a Special Issue on Membrane Separation

Chem. Eng. Technol. 2018, 41 (2).