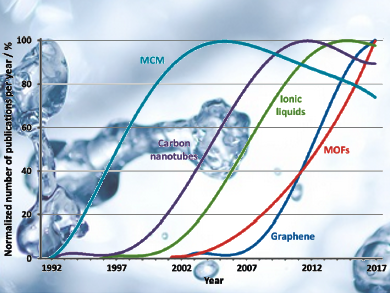

MOFs are crystalline coordination networks composed of metal ions or clusters held together by organic linker molecules. The prominent properties of MOFs are their extremely high pore volume per weight/volume and their very high BET (Brunauer, Emmett and Teller) surface. MOFs have been intensely studied in academia and industry, many MOFs have been developed in recent years. It has been predicted that MOFs could substitute zeolites and other molecular sieves in big adsorption, permeation, and heterogeneous catalysis applications.

Jürgen Caro, Leibniz University Hanover, Germany, highlights some properties of MOFs and their commercial use in a review. The commercialization of MOFs will proceed in small steps, with niche applications offering near-term profit to the companies which produce them. Caro sees these applications mainly in gas storage and release, maybe also as magnetic or luminescent materials or sensors. If these applications turn out to be successful and confidence in MOFs is built up, bigger applications in adsorption and permeation separation or catalysis can follow. With a rising number of applications, the production costs will drop. The first commercial applications of MOFs involve the release of stored compounds such as drugs.

To give two examples: Ripening fruits release traces of ethylene. Ethylene works like an auto-catalyst and speeds up the fruit ripening if it can dock on the receptors of a plant as a competitive inhibitor. 1-Methylcyclopropene (1-MCP) binds tightly to the ethylene receptors in fruits like apples or pears and delays their ripening. MOF Technologies, a spinoff of Queens University Belfast, Ireland, and Decco Ltd., Newbury, UK, brought TruPick on the market in 2016. TruPick contains a MOF that releases the adsorbed 1-MCP in wet air. So far, 1-MPC is encapsulated in cyclodextrin and is released if exposed to humid air.

MOFgen Ltd., a spin-out of the University of St. Andrews, UK, commercialized MOFs which prevent infections, prevent procedural complications, or promote healing by the controlled release of active agents from medical devices. One example is NO release for wound healing.

- Quo Vadis, MOF?,

Jürgen Caro,

Chem. Ing. Tech. 2018.

https://doi.org/10.1002/cite.201800034

This article is part of the special issue 90 Jahre Chemie Ingenieur Technik.