Rapid Controlled Transport of Water Droplets

Driven by natural or artificial sunlight, a new “microtube pump” transports water droplets over long distances. The system was developed by Chun Li, Zhiping Xu, Liangti Qu, Tsinghua University, China, and colleagues. The pump consists of a tube whose properties can be changed asymmetrically through irradiation. This results in capillary forces and a wettability gradient in the inner wall, which work together to accelerate the water droplets to exceptionally high speeds.

Modern molecular analytic and diagnostic methods generally work with tiny amounts of fluid. Microfluidic technology has also been used in synthetic processes in which reactions occur in microchannels and miniaturized instruments. In order to precisely transport such small volumes from one place to another, the team developed a “microtube pump”.

Sunlight-Powered Pump

The pump consists of a polymer tube with a diameter of about 500 µm. It is made of two layers: The outer layer is polydimethylsiloxane (PDMS), which the researchers mixed with reduced graphene oxide (rGO), a carbon-based nanomaterial that absorbs sunlight particularly well. This produces heat, which is transmitted to the inner layer of the hose wall, made of poly(N-isopropylacrylamide) (PNIPAm), a polymer that forms a hydrogel at room temperature. Its polymer chains are knotted into a network that swells as it absorbs water. Above about 32 °C, the hydrogel collapses into compact spheres that make the inner wall hydrophobic. This also causes the inner layer to shrink, making the inner diameter of the tube larger.

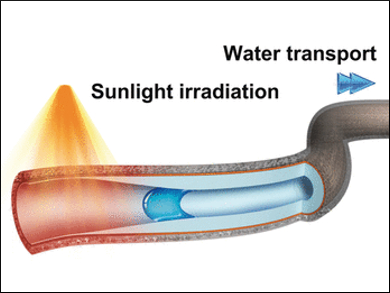

Irradiating the tube at only one end forms a gradient of wettability in the inner wall. In addition, the tube’s geometry becomes asymmetric because the inner diameter only increases at the irradiated end. Capillary forces cause water droplets to move toward the end with the smaller diameter—the end that is not irradiated. The decreased wettability of the inner wall at the irradiated end further accelerates the water droplet. The synergy of these two mechanisms results in high speeds, which can be controlled by changing the intensity of the irradiation. After irradiation, the tube cools off very quickly. The hydrogel returns to its original state, ready to be irradiated again.

The flexible material allows for the production of meters-long straight or bent tubes that can transport water continuously over long distances. It is also possible to make branched systems that can be irradiated simultaneously or in sequence at different locations. This, for example, allows for individual droplets containing different reagents to be transported in a specific order and combined—which could be used in diagnostic tests or when water droplets serve as microreactors for chemical reactions.

- Sunlight-Driven Water Transport via a Reconfigurable Pump,

Hongya Geng, Ke Zhou, Jiajia Zhou, Hongyun Ma, Cunjing Lv, Chun Li, Zhiping Xu, Liangti Qu,

Angew. Chem. Int. Ed. 2018, 57, 15435–15440.

https://doi.org/10.1002/anie.201808835