Metal–organic frameworks (MOFs) have gained interest during the past decade because of their useful properties, especially for adsorption processes. However, the use of MOFs in practical applications is often limited by their powdery nature, which makes the handling of these materials challenging.

To overcome this problem, Evamarie Hey-Hawkins, Leipzig University, Germany, Matti Haukka, University of Jyväskylä, Finland, and colleagues used selective laser sintering (SLS) 3D printing to anchor the MOF HKUST-1 onto a polymeric support. Using this printing process, it is possible to fabricate highly porous and customizable MOF-containing filters and other flow-through objects.

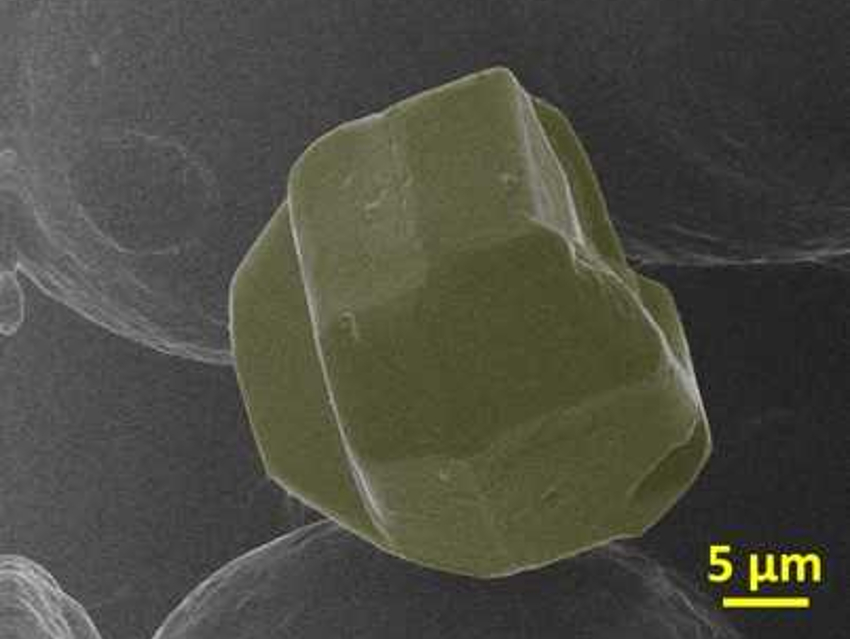

The filters were printed simply by mixing HKUST‐1 with an easily printable nylon‐12 polymer matrix. The MOF additive is firmly attached only on the surface of partially fused polymer particles and, therefore, remains accessible to fluids passing through the filter (MOF crystal on the surface pictured above).

The researchers compared the CO2-adsorption properties of the original powdery HKUST-1 and the 3D-printed objects containing the polymer-supported HKUST-1. The results showed that the adsorption capacity of the MOF is not reduced by the 3D-printing process. According to the researchers, the ability to easily fabricate MOF-containing objects in any shape or size could open up new ways to use MOFs.

- Selective Laser Sintering of Metal-Organic Frameworks: Production of Highly Porous Filters by 3D Printing onto a Polymeric Matrix,

Elmeri Lahtinen, Rafaella Precker, Manu Lahtinen, Evamarie Hey-Hawkins, Matti Haukka,

ChemPlusChem 2019.

https://doi.org/10.1002/cplu.201900081