Polymer microreactors are a cheap and practical way to develop chemical processes on a small scale before transferring them to industrial scales. To allow the observation of the processes and the flow within the reactor, they need to be transparent. They also should be inert and withstand rough conditions. Since microreactors are produced from thermoplastic polymers by ultrasonic embossing and welding, the material needs to be suitable for that as well. Most polymers fulfill some of these requirements, but not all of them.

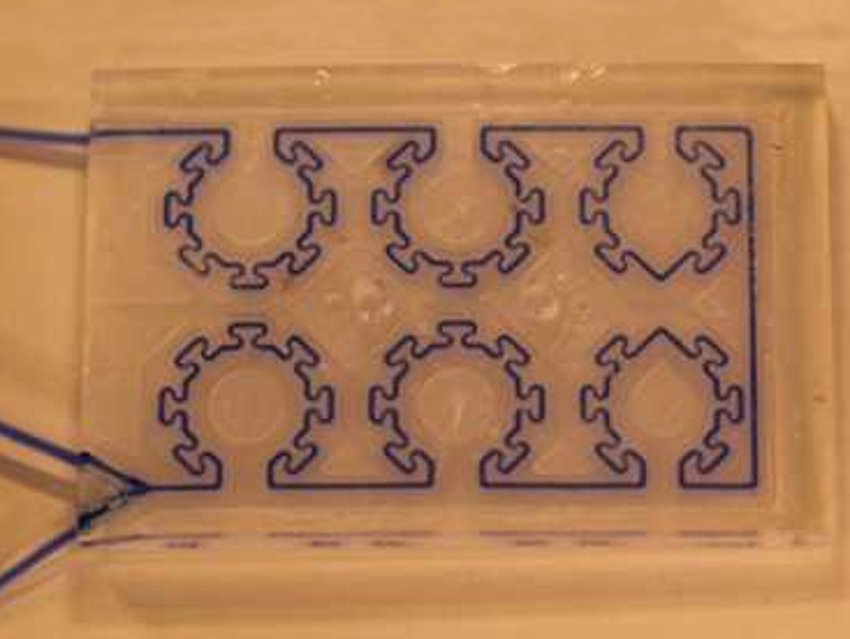

Norbert Kockmann, TU Dortmund University, Germany, Werner Karl Schomburg, RWTH Aachen University, Germany, and colleagues have developed an optically transparent microreactor (pictured) consisting of a poly(methyl methacrylate) (PMMA) plate, covered with polyvinylidene fluoride (PVDF) as an inert surface coating. The microchannel structures were pressed into the covered plate using ultrasonic hot embossing on a mold. The created grooves were then sealed by another PVDF foil.

To prove that the manufacturing process of the microreactors is reproducible, the residence time distributions of three different reactors were determined. They are almost identical for all reactors. The microreactors can withstand flow rates up to 10 ml min–1, resulting in pressure differences of up to 300 kPa. This indicates mechanical stability and a leak-proof seal. Higher flow rates lead to stronger secondary flows induced by the curvature of the channels, and therefore, to faster mixing times. At the highest flow rate of 10 ml min–1, mixing occurs in as little time as 19 ms, which is in the typical range for plate-type microreactors.

These results show that the combination of two polymers processed by ultrasonic welding and embossing is suitable to reproducibly fabricate low-cost and leak-proof microreactors.

- Ultrasonic Fabrication of Polymer Plate Reactors with a Surface Coating,

Lukas Hoehr, Felix Reichmann, Marius Berndt, Johannes Sackmann, Norbert Kockmann, Werner Karl Schomburg,

Chem. Eng. Technol. 2019, 42, 971–979.

https://doi.org/10.1002/ceat.201800333