Electrospun nanofibers are typically collected as nonwoven, physically stacked mats. This structure leads to weak connections among the nanofibers and, thus, often to insufficient mechanical strength. Welding at the cross points of the nanofibers using methods such as thermal annealing, chemical crosslinking, solvent or vapor treatment is an effective way to improve mechanical strength. These methods, however, generally cannot generate patterned welding on a nonwoven mat of nanofibers.

Younan Xia, Georgia Institute of Technology and Emory University, both Atlanta, USA, and colleagues have developed a general strategy for the photothermal welding of polymer nanofibers by doping the nanofibers with a near‐infrared (NIR)-absorbing dye and then irradiating them with an NIR laser. The team used poly(ϵ‐caprolactone) fibers as a model as doped them with the dye indocyanine green.

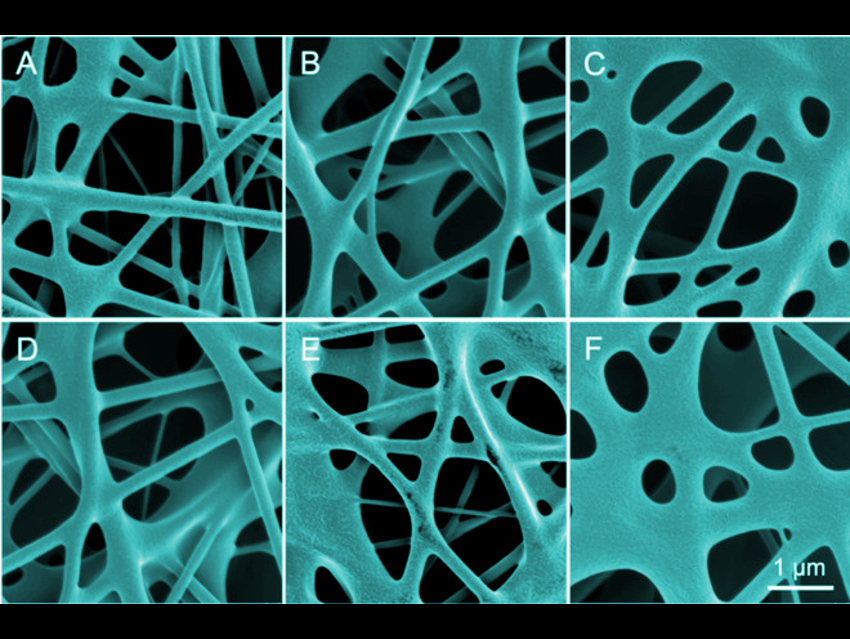

Photothermal welding allowed the team to selectively weld the fibers in certain areas only by using a mask. By changing the dye concentration, laser irradiance, and irradiation duration, the welding can be easily controlled, from welding at the cross points only to melting and fusion into a transparent solid film. This technique has a range of possible applications, such as enhancing the mechanical strength of nanofibers, patterned welding, photothermal printing, and biomedical uses.

- Photothermal Welding, Melting, and Patterned Expansion of Nonwoven Mats of Polymer Nanofibers for Biomedical and Printing Applications,

Tong Wu, Haoxuan Li, Jiajia Xue, Xiumei Mo, Younan Xia,

Angew. Chem. Int. Ed. 2019.

https://doi.org/10.1002/anie.201907876