For centuries, if not millennia, humanity has been fascinated by metals, in particular the ones we know colloquially as the precious metals—or more scientifically, the noble metals. Several of these metals have become useful for something other than their aesthetic qualities and the ease with which they might be fashioned into jewelry and other trinkets. They can, for example, be used as catalysts for a wide range of industrial chemical reactions, they can be fabricated into nanoparticles for sensors and spectroscopy, and they can be used to break down noxious fumes in vehicle exhausts.

Recovering Precious Metals

It is this latter application, i.e., catalytic converters for cars and other vehicles, that represents an area ripe for “mining”. Currently, aqua regia, a mixture of concentrated nitric acid and hydrochloric acid, usually in a molar ratio of 1:3, is used to dissolve noble metals. This allows these relatively rare elements to be retrieved from worn-out and scrapped catalytic converters and other equipment. The mixture generates nitrosyl chloride, chlorine gas, and other noxious fumes on its own. It is also highly corrosive, as you would expect, given that it can dissolve gold. There is a need to find more environmentally benign alternatives to this “regal water”.

Koen Binnemans and colleagues, KU Leuven, Belgium, have tackled this problem. The team explains that other researchers have investigated the likes of “organic aqua regia“, which is derived from thionyl chloride and a polar aprotic organic solvent such as pyridine, imidazole, or N,N-dimethylformamide (DMF). However, these earlier approaches all have limitations, including the fact that they cannot dissolve platinum and the components are not environmentally friendly. Others have tried polyhalide ionic liquids as well as so-called “dry aqua regia” (FeCl3/KCl mixtures). There has also been a suggestion that aluminum chloride solutions in a low concentration of nitric acid as the oxidant might work.

A Safer Solution

The team has devised a more potent alternative to aqua regia that is far less noxious and hazardous. They took their inspiration from a 1973 paper by Angell and colleagues [1], wherein it was remarked almost in passing that concentrated solutions of aluminum chloride and aluminum nitrate could dissolve noble metals faster than boiling aqua regia. The Angell paper alluded to a follow-up paper that never emerged.

The researchers have taken that next step and shown that highly concentrated solutions of aluminum chloride and aluminum nitrate can also readily dissolve gold as well as the platinum group noble metals. They prepared a concentrated mixture of hydrated AlCl3 and Al(NO3)3 with ratios of 75–85 wt% hydrated salts to 15–25 wt% water and tested the solutions on metal wires and spent automotive catalysts.

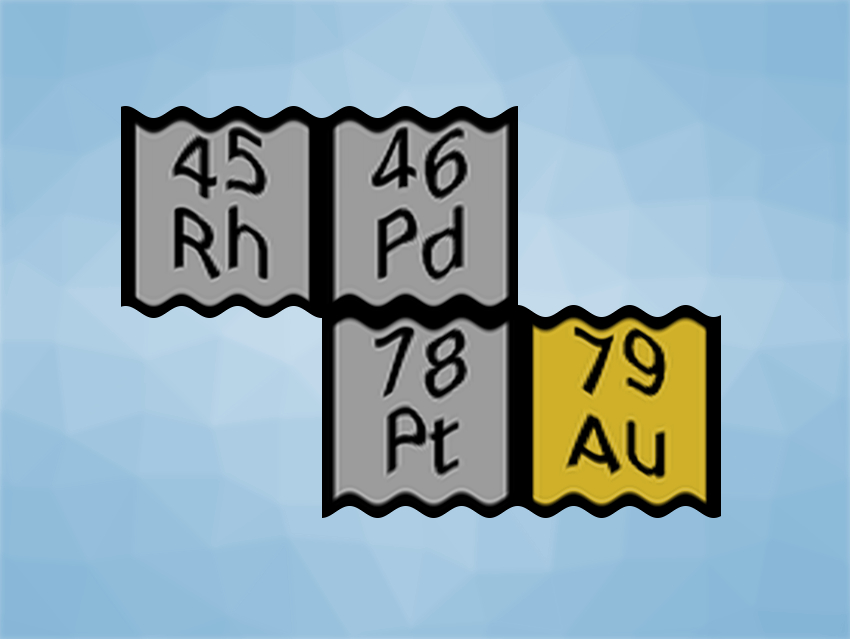

The team found that palladium wires were fully dissolved within 4.5 h, while dissolving gold or platinum wires took one or two days, respectively. Rhodium wires did not dissolve. The solutions could leach 95 % of the palladium from a spent automotive catalyst in just 15 min at the relatively low temperature of 80 °C. It took longer to leach platinum from such a device, with 64 % dissolution after 4 h. Rhodium was leached at less than 20 %. This is similar to aqua regia, which can dissolve gold, palladium, and platinum well, but can only dissolve rhodium effectively if it is in a finely powdered form.

Optimization

The researchers suggest that a multi-stage leaching process might be employed, with fresh solvent used each time to boost the dissolution of platinum and rhodium. They also add that a scaled-up process will need optimizing to reduce any aluminum contamination of the noble metals retrieved from spent catalytic converters and other devices, such as fuel cells.

“We would like to test the effect of other concentrated solutions on the same type of material (spent auto catalysts) to see if we can increase the selectivity of the process,” team member Sofía Riaño Torres told ChemistryViews. “The next step is definitely to try it on a larger scale and improve the way we recover the pure metals from the leachate in order to achieve higher yields and purities.”

- Dissolution of noble metals in highly concentrated acidic salt solutions,

Federica Forte, Sofia Riaño, Koen Binnemans,

Chem. Commun. 2020.

https://doi.org/10.1039/d0cc02298e

Reference

- [1] Proton magnetic resonance chemical shifts and the hydrogen bond in concentrated aqueous electrolyte solutions,

E. J. Sare, C. T. Moynihan, C. A. Angell,

J. Phys. Chem. 1973, 77, 1869–1876.

https://doi.org/10.1021/j100634a011