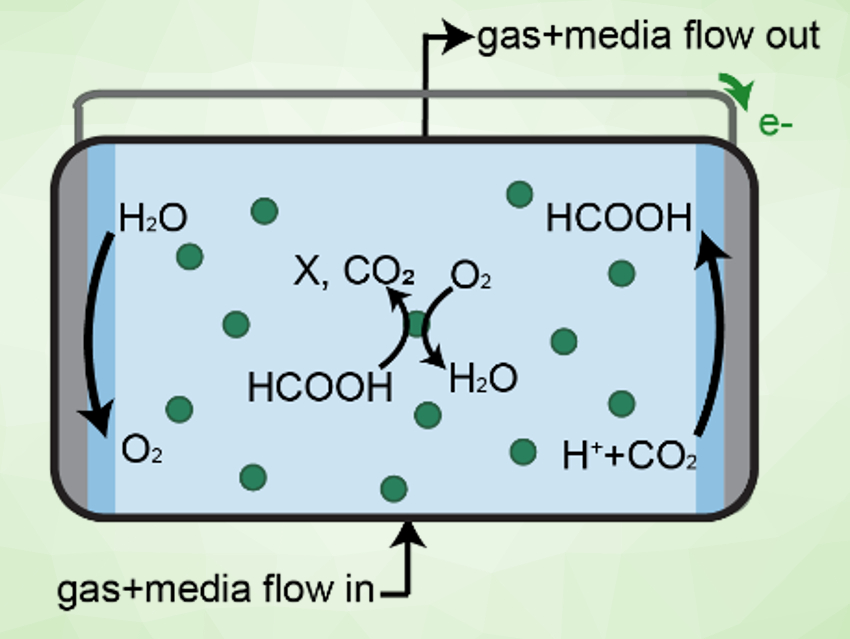

Converting CO2 into value-added chemicals and fuels could help to mitigate the effects of carbon emissions. Mediated microbial electrosynthesis (MES) is one of many strategies to fixate CO2 using renewable energy. In this approach, a mediator molecule is first electrochemically reduced (e.g., CO2 is reduced to formic acid) and then consumed by microorganisms to convert it into biomass or useful products. Although this formate-mediated MES is promising, there are still open questions, such as how to design and operate a reactor that optimizes performance.

Anthony J. Abel and Douglas S. Clark, University of California, Berkeley, USA have developed a comprehensive mathematical model of this process, including acid/base-, electrochemical, and microbial reaction kinetics, species transport, and gas/liquid mass transfer. The model describes an MES system generating formic acid and H2 (as a secondary product) for consumption by planktonic cells. It can be used to evaluate the effects of reactor design and operating parameters on performance metrics, such as biomass productivity, cell density, carbon utilization, and energy efficiency, and to compare the performance of microbes using different growth strategies and conditions.

The model revealed a trade-off between the availability of CO2 (as a mediator molecule) and O2 (for microbial respiration) and that balancing these requirements can maximize productivity. The analysis also determined energy and CO2 utilization efficiency limits. It showed that these limits could be improved with microbial engineering and by separating electrochemical and microbial processes into two reactors. However, the single-pass carbon utilization efficiency remains at ca. 10 % in the best case. This means that recycling of the gas will be necessary for a high overall CO2 utilization in scaled-up systems.

- A comprehensive modeling analysis of formate-mediated microbial electrosynthesis,

Anthony J. Abel, Douglas S. Clark,

ChemSusChem 2020.

https://doi.org/10.1002/cssc.202002079