Let the sunshine in—and generate current at the same time. Windows with integrated photovoltaics can contribute to the power supply in buildings. However, solar windows usually darken rooms because they use photons from the visible spectrum of light. A true transparent solar window can only be achieved if photons outside the visible light range are used for power generation.

However, with current photovoltaics, experts have found it difficult to raise transparency to more than 40–50 %. Using light concentrator molecules as well as a different photovoltaic setup, Richard R. Lunt, Michigan State University, East Lansing, USA, and colleagues have raised the window transparency to 70 % and obtained a high photovoltaic efficiency of 3 %.

Shifting Power Generation to the Edge, Leaving Light Harvesting for the Pane

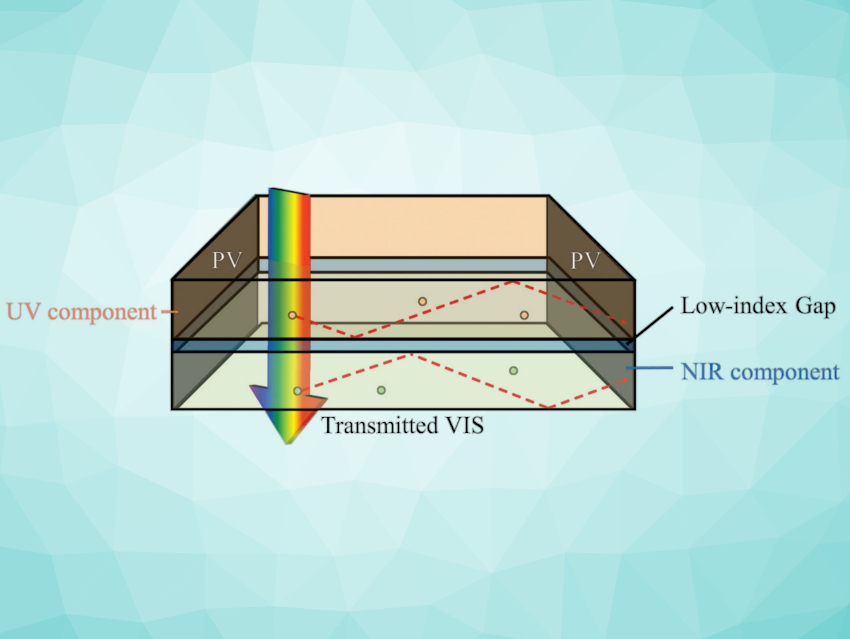

In their setup, photovoltaic strips mounted to the edge of the window pane convert photons to electricity. The rest of the pane serves to concentrate non-visible photons. This technique avoids the necessity to integrate electrodes in photovoltaic layers on the pane. Even the most transparent electrodes obstruct the clear view, cause photon loss, and segment the window.

As solar concentrators, the researchers used transparent layers called waveguides, which contained luminescent substances designed to process non-visible photons. For a dual-band photovoltaic window, luminophores collected photons from both the ultraviolet (UV) and near-infrared (NIR) light ranges, and emit in the near-infrared region. Thus, the system effectively skips the entire visible range to provide as yet unseen levels of transparency.

Luminophores for Invisible Light

As a UV-light luminophore, the team used a multicore molybdenum-based nanocluster with the chemical formula Cs2Mo6I8(CF3CF2COO)6. The cluster harvests photons in the ultraviolet region of the spectrum and emits in the near-infrared. This is a massive downshift of over 300 nm, the researchers remark. They find these substances well-suited for this kind of application, especially because they do not contain toxic substances—unlike the lead-containing perovskite materials used in many advanced photovoltaic applications.

As NIR-fluorescent organic molecules, the researchers used the established non-fullerene acceptor COi8DFIC, which is based on fused thiophene rings, and a boron complex with aromatic ligands, BODIPY, which is a known fluorescent NIR acceptor.

Dual-Band Devices for Transparent Windows

To assemble the dual-band device (pictured schematically), the researchers first drop-cast a half-millimeter-thick layer of the polymeric waveguide material containing the NIR components onto a borosilicate glass slide. On another glass slide, they drop-cast the waveguide polymer containing the UV component.

Both slides were then mounted face-to-face and encapsulated at the edges, leaving a gap between them filled with nitrogen or simply air. “The air gap optically isolates the waveguided luminescence in each panel to ensure total reflection and prevent parasitic reabsorption,” the team explains. With the photovoltaic strips mounted at the glass edges, the researchers reported photovoltaic efficiencies of 3 %. The windows were 70 % transparent, a far higher value than can be achieved by current photovoltaics windows.

Optical Transparency, But with a Tint

However, the researchers also observed that the glass was slightly tinted. This tinting—yellow from the UV component extending absorption into the blue range and blue from the fluorescent dyes reaching into the red range—was within the permissible range for industrial windows, but further optimization is needed.

This optimization is feasible, according to the team. They suggest that fine-tuning the organic fluorophores would result in a better quantum yield, sharper absorption, and better decoupling of absorption and emission. The researchers ultimately envisage devices with up to 10 % photovoltaic efficiency and visible transparency of over 75 %.

However, the resulting windows would not be large. The tested frames were only 10 cm2 in size, and scaling up would result in a loss of efficiency. For the largest frames possible, the team estimates a size of 1 m for the UV component and a maximum size of 30 cm for the NIR component. “At these sizes, tiling in window facades would still be possible,” the researchers argue.

- Ultraviolet and Near‐Infrared Dual‐Band Selective‐Harvesting Transparent Luminescent Solar Concentrators,

Chenchen Yang, Wei Sheng, Mehdi Moemeni, Matthew Bates, Christopher K. Herrera, Babak Borhan, Richard R. Lunt,

Adv. Energy Mater. 2021.

https://doi.org/10.1002/aenm.202003581