To reduce the consumption of dwindling fossil resources, finding new renewable platform molecules is important. Fructose, for example, could be used as an alternative source of crucial chemicals such as 5-hydroxymethylfurfural or levulinic acid. However, generating fructose from widely available glucose continuously using a non-enzymatic heterogeneous catalyst is still challenging.

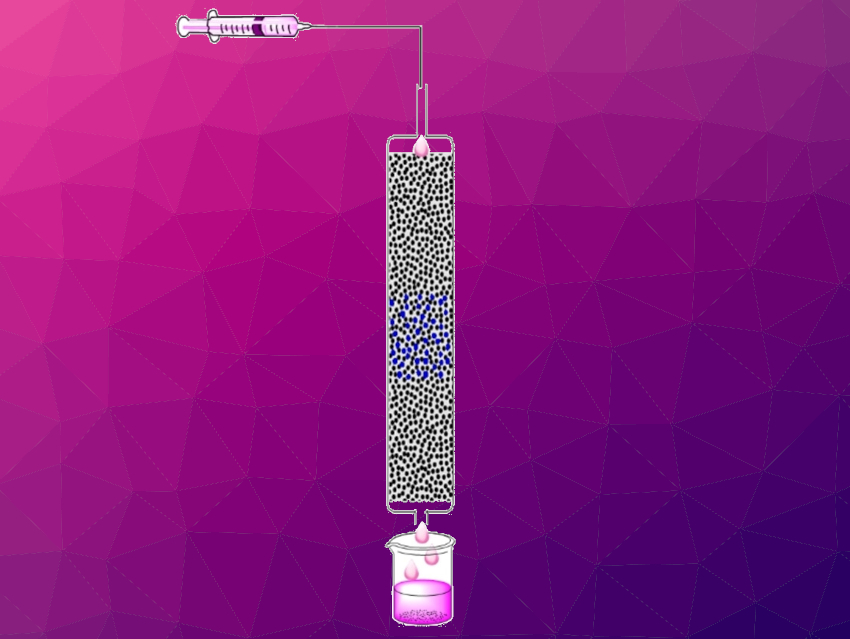

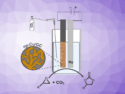

Maria Ventura, Jaime Mazarío, and Marcelo E. Domine, Universitat Politècnica de València, Spain, have synthesized a hydrotalcite-derived Ca–Al mixed oxide that can be used as a heterogeneous catalyst in a fix-bed continuous flow-reactor to isomerize glucose to fructose efficiently. Co-precipitation of the metal precursors Ca(NO3)2 and Al(NO3)3 in the presence of NaOH and aging under N2 was used to prepare the hydrotalcite-based precursor. Calcination then gave the desired mixed oxide. The catalyst was mixed with SiC and used in a tubular continuous-flow catalytic reactor. An aqueous solution of glucose was then pumped through the reactor.

An optimized Ca−Al mixed oxide could be employed as a reusable solid catalyst for the continuous isomerization of glucose with an average glucose conversion of 68 % and a fructose yield of 54 %. This performance is comparable to the enzymatic system currently used in industry.

- Isomerization of Glucose‐to‐Fructose in Water over a Continuous Flow Reactor using Ca−Al Mixed Oxide as Heterogeneous Catalyst,

Maria Ventura, Jaime Mazarío, Marcelo E. Domine,

ChemCatChem 2021.

https://doi.org/10.1002/cctc.202101229