Spouted beds are used for miscellaneous applications such as drying, granulation, coating of solids and for chemical reactions in various processes in the chemical, pharmaceutical, agricultural and food industry.

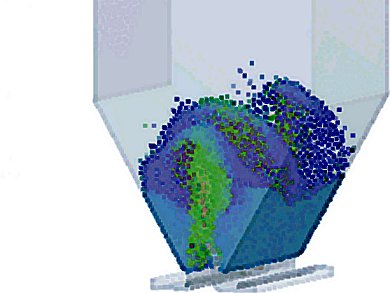

The discrete particle model (DPM) is a powerful tool to create tailor-made spouted beds for specific process requirements. The limitation of DPM for large-scale simulations, resulting from high computational effort, can be avoided by simulation of rectangular apparatuses of appropriate thickness. Then the fluid and particle dynamics are independent in this direction and scale-up can simply be achieved by extending of the apparatus thickness.

To investigate the influence of gas flow rate, particle friction coefficient and the geometry basis angle on the particle dynamics in spouted beds, a coupling of discrete element method and computational fluid dynamics was used for modeling by Vitalij Salikov, Sergiy Antonyuk and Stefan Heinrich, Hamburg University of Technology, Germany.

Using DPM it was possible to predict the transition from stable spouting to an instable mode by increasing the air flow rate beyond a limiting value. The probability density function of the vertical particle velocity was found to remain constant in shape and location in the stable spouting regime and can therefore be used as a stability criterion. The spread of these curves can be used to quantify the mobility of the particles in the bed.

There is only limited potential to increase the particle rotation by manipulating the gas throughput. Elevated particle friction assisted spouting stability but suppressed considerably the particle mobility and rotation.

The basis angle was found to be a suitable tool for the adjustment of both particle mobility and rotation. The reduction of the angle can lead to spouting instabilities and therefore an optimal configuration should be found for each material in order to achieve an optimal process design.

- Using DPM on theWay to Tailored Prismatic Spouted Beds,

Vitalij Salikov, Sergiy Antonyuk, Stefan Heinrich,

Chem. Ing. Tech. 2012, 84 (5), 388–394.

DOI: 10.1002/cite.201100203