Photoresists are light-sensitive materials used in industrial processes such as photolithography. Exposing the material to light changes its solubility in a developer liquid, and leaves a patterned coating on the substrate after the development process. This pattern then functions as a mask for subsequent etching, sand blasting, etc.

A team led by Christof Wöll, Karlsruhe Institute of Technology (KIT), Germany, has discovered a method to incorporate multifunctionality and heterogeneity into surface-mounted metal-organic frameworks (SURMOFs) and demostrated their use as photoresists. Functional species, such as alkynes, can be selectively installed into the MOF structures based on a photo-controlled post-synthetic modification (PSM). The team demonstrated the potential of this new class of photoresists by photopatterning, using both negative and positive lithography.

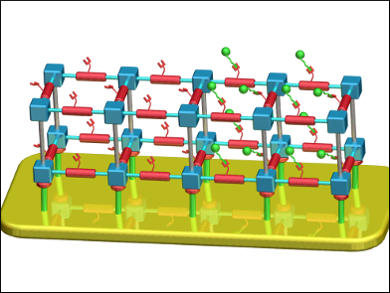

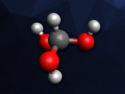

The method is based on the liquid-phase epitaxial (LPE) growth of azido-SURMOF thin films, e.g., [Zn2(N3BPDC)2(Dabco)] (N3BPDC = 2-azido-4,4′-biphenyl-dicarboxylic acid, Dabco = 1,4-diazabicyclo[2.2.2]octane), on modified gold substrates. Coupling reactions with the azides in the molecular framework can be either induced by photo-initiated Cu(I)-catalyzed azide-alkyne click chemistry, or prevented through the photodecomposition of azide, yielding a positive or negative resist.

The results also demonstrate that by combining a top-down (UV lithography) with a bottom up (liquid phase heteroepitaxy) approach, the photopatterning of SURMOF thin films is not limited to two dimensions, but can be extended to the third dimension by stacking differently functionalized SURMOFs on top of each other.

- Monolithic, Crystalline MOF Coating: An Excellent Patterning and Photoresist Material,

Zhengbang Wang, Jinxuan Liu, Sylvain Grosjean, Danny Wagner, Wei Guo, Zhigang Gu, Lars Heinke, Hartmut Gliemann, Stefan Bräse, Christof Wöll,

ChemNanoMat 2015.

DOI: 10.1002/cnma.201500031