Hybrid Aerogels Made from Biopolymers and Silica

Airy, airier, aerogel: the sponge-like networks that make up these highly porous solids can consist of up to 99.98 % pores. The most common aerogels are based on silica and are most often used as insulation because of their unusually low thermal conductivity. The serious disadvantage of these materials is their fragility.

In the journal Angewandte Chemie, a team of Swiss and French scientists has now introduced a new class of hybrid aerogels made from silica and plant-derived pectins. The new materials have comparable thermal properties but are far more mechanically stable. In addition, they are made by an aqueous, “green” process from bioderived materials.

Fragile Silica Aerogels

Silica aerogels are made when hydrochloric acid is used to precipitate silica particles out of a sodium silicate solution. The particles aggregate into a gel with a network structure, which is subsequently washed and dried. Their very high porosity and specific surface area makes them useful for catalysis, pharmaceuticals, and chemistry; their superinsulating properties are useful for transparent thermal insulation in solar thermal systems or as insulation for renovations where there isn’t enough space for conventional insulation materials.

The fragility of these silicate aerogels is problematic. The cause of this fragility is the pearl-necklace-like structure of the network. Silica nanoparticles with diameters of about 3 to 10 nm are linked together by significantly narrower bridges. In the search for aerogels with better mechanical properties researchers have focused on bioderived materials such as pectins, plant fibers that are used by the food industry as a gelling agent, among other things. However, pectin aerogels are short on thermal insulation properties.

Strong and Extremely Insulating Hybrids

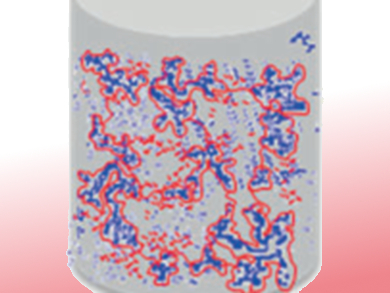

Within the framework of the European Aerocoins project, a team working with Matthias Koebel at the Swiss Federal Laboratories for Materials Science and Technology, EMPA, Dübendorf, Switzerland, and Tatiana Budtova at MINES ParisTech, Sophia Antipolis, France, has now produced a hybrid aerogel made of interpenetrating pectin and silica networks. This material has tailored mechanical properties and releases minimal amounts of dust, as well as demonstrating outstanding thermal properties.

In addition to optimizing the relative concentrations of pectin and silica, controlling the pH value during the gelling process was key. At a pH of 1.5, silica gels within about 14 days; at pH values above 4 it gels in a few minutes. At pH values below 2.0, pectin gels very slowly, between pH 2 and 3 it gels within minutes, and at pH values above 3.5 it doesn’t gel at all. The scientists obtained optimal results at a pH of 1.5: both of the components gel slowly together into homogeneous hybrids. After washing and hydrophobization the aerogel is dried with supercritical carbon dioxide. In contrast to the delicate pearl-necklace structure of the pure silica aerogels, the hybrid gels have significantly thicker and more robust linkages, making them mechanically stable.

- Strong, Thermally Superinsulating Biopolymer-Silica Aerogel Hybrids by Cogelation of Silicic Acid with Pectin,

Shanyu Zhao, Wim J. Malfait, Arnaud Demilecamps, Yucheng Zhang, Samuel Brunner, Lukas Huber, Philippe Tingaut, Arnaud Rigacci, Tatiana Budtova, Matthias M. Koebel,

Angew. Chem. Int. Ed. 2015.

DOI: 10.1002/anie.201507328