Surface Protection

Coatings functionalize surfaces or protect them from processes such as corrosion, abrasion, and weathering, and may provide an aesthetic appearance—automotive coatings and non-stick frying pans are good examples. Contact lenses, implants, LEDs, or photovoltaic cells require extremely thin coatings. Tthe teams led by Gero Decher at the Institut Charles Sadron in Strasbourg, France, has introduced a process for the production of ultrathin coatings that is especially simple, versatile, and suitable for large-scale processes.

A simple yet powerful method for the assembly of nanoscale films is the already well-known layer-by-layer technique. Two mutually interacting species, for example positively and negatively charged polymers, are consecutively adsorbed from solution, forming hybrid thin films through a self-organization process. One major improvement to this method was introduced with the technique of spray-assisted deposition, in which atomized mists of solutions containing each of the two substances are sprayed on a surface in an alternating fashion. This accelerates the process and facilitates scaling up to industrial levels.

Simultaneous Spraying

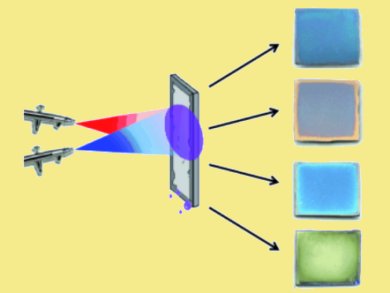

The French–German researchers led by Decher and Pierre Schaaf at the Centre National de la Recherche Scientifique and Jean-Claude Voegel at the Institut National de la Santé et de la Recherche Médicale have now been able to make another substantial improvement to this technique: In “simultaneous spray coating of interacting species” (SSCIS), the two complementary components are not applied consecutively, but are simultaneously sprayed against a receiving surface. Depending on the process conditions, the partner substances rapidly form a continuous layer. The thickness of the film is controlled by changing the spraying time and can range from a few nanometers to a few micrometers. This results in highly homogenous coatings that can even possess optical quality.

The one-step process is cheap, robust, user-friendly, and unbelievably versatile. In principle, all pairs of substances that interact with each other, such as inorganic ions of opposite charge, are suitable for use with the simultaneous spray process. It is thus possible to produce films of calcium fluoride (for optical components) or deposits of calcium phosphate (for use in biomaterials).

Interestingly, the new technique also works with pairs that do not produce intact layers when the conventional layer-by-layer process is used. Thus the presented results open up a wealth of new possibilities to produce surfaces with tailored specific functionalities, for example for catalysis, to make implants more biocompatible or for tissue engineering.

- Spray-On Organic/Inorganic Films: A General Method for the Formation of Ultrathin Coatings

M. Lefort, G. Popa, E. Seyrek, R. Szamocki, O. Felix et al.,

Angew. Chem. Int. Ed. 2010, 49.

DOI: 10.1002/anie.201002729 - M. Lefort, G. Popa, E. Seyrek, R. Szamocki, O. Felix et al.,

Angew. Chem. 2010, 122.

DOI: 10.1002/ange.201002729

It’s great that the manufacturers of these products are doing so well! Films, plastics, chemicals, and cardboard are great materials for creating surface protection products to protect homes during construction. The success of these companies makes it more affordable for construction professionals to build because they lower the amount of repairs that have to be done later due to damage from trades. Great stuff! http://buildsitepro.com/home.asp