LyondellBasell officially broke ground on what will be the largest propylene oxide (PO) and tertiary butyl alcohol (TBA) plant ever built. The Houston area project is estimated to cost $2.4 billion, representing the single-largest capital investment in the company’s history. Once in operation, the plant will produce 1 billion pounds (470,000 metric tons) of PO and 2.2 billion pounds (1 million metric tons) of TBA annually. Startup of the plant is planned for 2021.

The 140-acre PO/TBA plant will be built at the LyondellBasell Channelview Complex located in Channelview, TX, USA. An associated 34-acre ethers unit, which will convert TBA to oxyfuels, will be built at the company’s Bayport Complex in Pasadena, TX, USA. These locations along the Texas Gulf Coast have been chosen because of their proximity to low-cost feedstocks and the transportation infrastructure needed to ship products to markets around the globe.

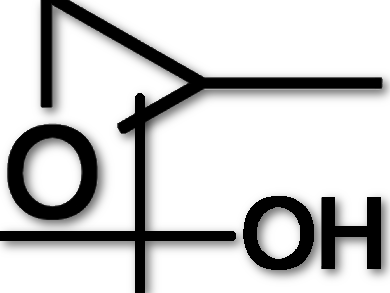

PO is used to make bedding, furniture, carpeting, coatings, building materials, and adhesives. TBA will be converted to two ether-based oxyfuels, methyl tertiary butyl ether (MTBE) and ethyl tertiary butyl ether (ETBE). Both MTBE and ETBE are high-octane gasoline components that help gasoline burn cleaner and reduce emissions from automobiles.

LyondellBasell plans to sell the PO and derivative products to both domestic and global customers. The oxyfuels will be primarily sold into Latin America and Asia. A portion of the TBA will remain in the domestic market in the form of high purity isobutylene which is used in tires and lubricants. The majority of the products will be exported via the Houston Ship Channel.

- LyondellBasell, Rotterdam, The Netherlands