Large defects in bones due to, e.g., cancer or trauma, usually require a bone graft to fix. These bone grafts can either be created from another bone of the patient (autografts) or transplanted from a deceased donor (allografts). However, especially for large, load-bearing bones, both of these approaches have significant drawbacks: There may not be enough material for an autograft, while allografts are less strong and less bioactive due to the processing required for foreign bones.

Hala Zreiqat, University of Sydney and Australian Research Council Training Centre for Innovative BioEngineering, both Sydney, Australia, and Harvard University, Cambridge, MA, USA, and colleagues have developed a 3D-printed bioactive ceramic scaffold as a bone graft substitute. The material, called strontium–hardystonite–gahnite or “Sr-HT-Gahnite”, was prepared from a powdered mixture of strontium–hardystonite (Sr–Ca2ZnSi2O7) and aluminum oxide (Al2O3). This precursor ceramic powder was dispersed in a water‐based solution containing hydroxypropyl methylcellulose and a surfactant. The dispersion was used as an ink for 3D printing the desired scaffolds. The team then used a heat treatment to decompose the organic materials in the printed scaffolds and sinter the ceramic particles.

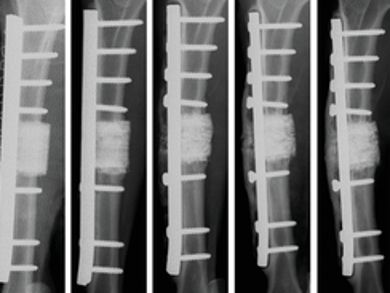

The resulting Sr‐HT‐Gahnite scaffolds consist of strontium–hardystonite grains and a glass phase at the grain boundaries containing submicron gahnite (ZnAl2O4) crystals. The material was tested as a graft for 3 cm-long defects in the tibia (lower leg bone) of sheep and compared with autografts. The team found that their purely synthetic bone substitute can match the structural and functional outcomes of bone regeneration achieved with autografts. The material is bioactive and could induce complete healing in large bone defects.

- A Novel Bone Substitute with High Bioactivity, Strength, and Porosity for Repairing Large and Load-Bearing Bone Defects,

Jiao Jiao Li, Colin R. Dunstan, Ali Entezari, Qing Li, Roland Steck, Siamak Saifzadeh, Ameneh Sadeghpour, John R. Field, Austin Akey, Martin Vielreicher, Oliver Friedrich, Seyed-Iman Roohani-Esfahani, Hala Zreiqat,

Adv. Healthcare Mater. 2019.

https://doi.org/10.1002/adhm.201801298