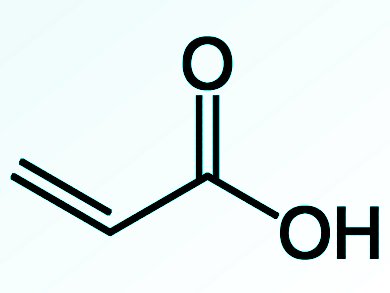

BASF, Cargill and Novozymes have signed an agreement to develop technologies to produce acrylic acid from renewable raw materials.

Novozymes and Cargill have collaborated on renewable acrylic acid technology since 2008. They have worked to develop microorganisms that can efficiently convert renewable feedstock into 3-hydroxypropionic acid (3-HP), which is one possible chemical precursor to acrylic acid. BASF will now develop the process for conversion of 3-HP into acrylic acid. The world´s largest producer of acrylic acid plans initially to use the bio-based acrylic acid to manufacture superabsorbent polymers.

Presently, acrylic acid is produced by the oxidation of propylene derived from the refining of crude oil. The annual global market volume of acrylic acid is around 4.5 million tons with a value of $11 billion at the end of 2011. The market has been growing at a rate of 4 % per year according to BASF.