Teijin Ltd. announced that it has established a joint venture with the chemical producer SK Chemicals to develop and sell polyphenylene sulfide (PPS) resins and compounds. The joint venture, INITZ Co., Ltd., belongs 34 % to Teijin and 66 % to SK Chemicals. Construction of the 12,000-ton/yr PPS resin plant began on October 1 in Ulsan, South Korea.

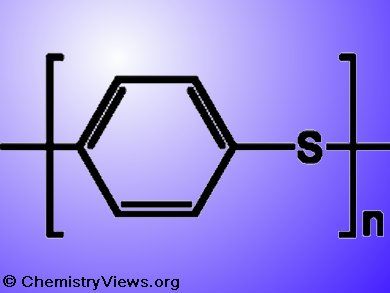

PPS resin exhibits excellent thermal resistance, chemical resistance, mechanical strength and dimensional stability. The demand for PPS resin is expected to grow in line with the increasing popularity of electric and hybrid vehicles and the ongoing expansion of electronics markets in emerging countries.

INITZ plans to produce the first chlorine- or sodium-free PPS resins utilizing proprietary technologies of SK Chemicals. With conventional PPS resins, chlorine and sodium from raw materials and byproducts remain in the resin. This can lead to the corrosion of molds and functional deterioration of metal parts, such as defective contacts. Also, chlorine has potentially harmful environmental effects if burned.

Focusing on customers especially in fast-growing Asian markets, INITZ aims to become a world leader in PPS resin and compounds. A global market share of 20 % and annual sales of 300 billion KRW ($280 million) are envisioned by 2020.

- Teijin Ltd., Tokyo, Japan

- SK Chemicals, Gyeonggi-do, South Korea

- INITZ Co., Ltd., Ulsan, South Korea