Engineers around Brian Paul, Oregon State University, USA, have discovered a new method to speed the production rate of nanoparticles by 500 times over conventional batch syntheses based on the production rate per reactor volume.

A high-rate production of phosphine-stabilized undecagold nanoclusters was achieved using a layer-up strategy which involves the use of microlamination architectures. The approach uses an arrayed microchannel reactor and a “laminated architecture” in which many sheets, each with thousands of microchannels in them, are stacked in parallel to provide a high volume of production and excellent control of the processes involved. The continuous production of highly monodispersed phosphine-stabilized undecagold nanoclusters at a rate of about 11.8 (mg s − 1) was achieved using a microreactor with a size of 1.687 cm3.

This advance could play an important role in making nanotechnology products more commercially practical. The applications could be possible in improved sensors, medical imaging, electronics, and even solar energy or biomedical uses when the same strategy is applied to abundant materials such as copper, zinc or tin.

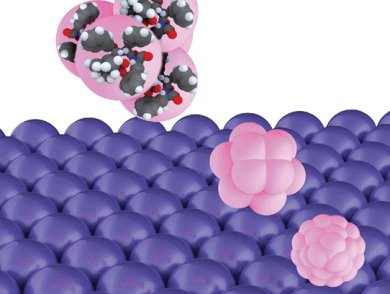

Photo: Small 8/2010 (C) Wiley-VCH

- High-rate synthesis of phosphine-stabilized undecagold nanoclusters using a multilayered micromixer,

Hyung Dae Jin, Anna Garrison, T. Tseng, Brian K. Paul, Chih-Hung Chang,

Nanotechnology 2010.

DOI: 10.1088/0957-4484/21/44/445604