In theory, moisture in the air could represent an inexhaustible source of fresh water. To harness it as efficiently as possible, Kyle E. Cordova, Advanced Research Centre, Royal Scientific Society, Amman, Jordan, and colleagues have developed an atmospheric water harvesting device that automatically adjusts its operation to adapt to changing environmental conditions. This flexible design enhances the water yield for a lower energy consumption and brings the technology closer to practical use in regions where access to fresh water is limited.

Extracting Water Vapor

In atmospheric water generation, liquid water is extracted directly from the atmosphere. The principle behind this is based on water vapor in the air condensing on a surface when its temperature is at or below the dew point (the temperature at which the relative humidity of the air is 100 %, in other words, when the air is fully saturated). However, when relative air humidity drops below 30 %, the dew point may drop to little more than 0 °C. The result is that, in dry climates, cooling costs combined with low water production make this technology unfeasible in its current form.

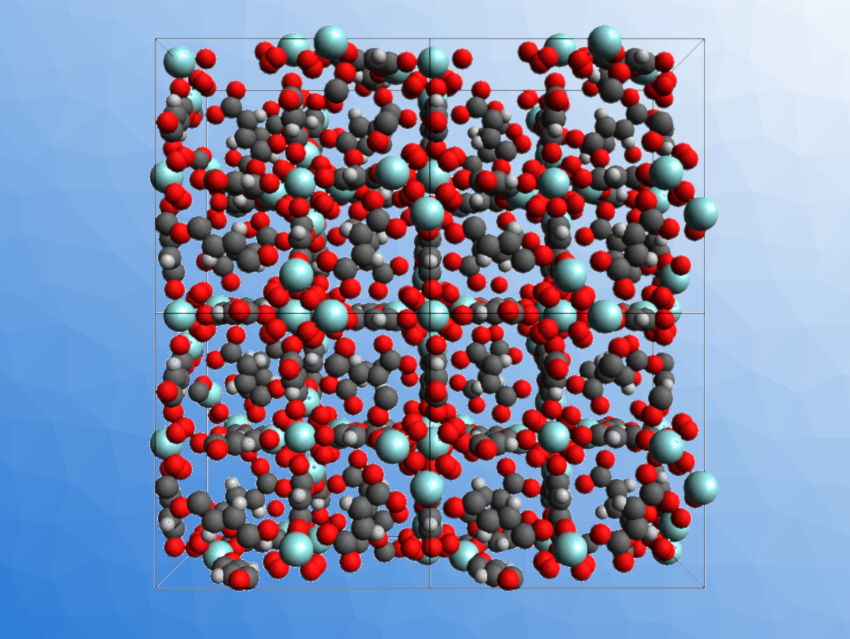

A possible solution is the use of hygroscopic and porous materials, which adsorb large quantities of water from the air and release it again when gently heated. This process effectively concentrates the water vapor, making water collection possible even in climates. One of the best materials for atmospheric water harvesting at low humidity is MOF-801 (pictured), a zirconium-based metal-organic framework. It has been employed in prototypes in desert climates, but water production yields and energy consumption are still uneconomical for larger-scale applications.

To make atmospheric water harvesting more efficient, the team was interested in finding ways to save energy in the process itself rather than focusing on designing new and more efficient extraction materials. As a crucial point for optimization, Cordova identified the response of the sorption material to the environmental conditions. “The active device is operated by pushing air through, but at prescribed times. There is no consideration for the surrounding environment,” he states.

Fluctuating Dew Points

The team noted that the adsorbing material reached saturation more slowly or quickly depending on relative humidity and temperature. However, both parameters fluctuate over the course of a day, with high relative humidity and low temperatures at night, and low relative humidity and high temperatures in the daytime. Because temperature and humidity combine to give the dew point, and this, in turn, defines the ability of the material to take up water, the researchers came to the conclusion that they should set adsorption and desorption times in each cycle based on both these environmental parameters.

To continually assess the dew points for sorption material and condenser, the team installed two sensors, one measuring the temperature and relative humidity of the incoming air during the adsorption phase, the other collecting air data within the condensation chamber. The sensor data fed into two algorithms, the first calculating the optimum time for the adsorption phase, the other setting the desorption time and the condenser cooling temperature.

Self-Optimizing Operation

As a result, the device was able to change its cycle times automatically depending on fluctuations in the environmental conditions: When relative humidity was low (in the daytime), cycles were shorter, and when humidity was high (at night), cycles were longer. Over the course of a whole day, this adaptive operation resulted in 1.5 fewer cycles, but produced a 26 % higher yield and consumed 44 % less electrical power. Compared with other atmospheric water harvesting systems and materials, the adaptive-mode device outperformed its competitors—especially at relative air humidities of below 30 %.

Turning to real-world applications, the team calculated that, in a desert climate, 1.9 kg of material are necessary to produce 3.5 L of clean, drinkable water per day, which is the recommended daily amount for one person. To produce this volume, 7–18 kWh of electric power is consumed—equivalent to the energy needed to power an electric vehicle for 60–120 km. The price for one liter of this air-harvested water could be around half of the current market price for drinking water, the team adds.

The work shows that using smart operation modes can maximize productivity for moisture harvesting systems in dry climates. This is exciting news in a field that has invested heavily in materials design. Guihua Yu from the University of Texas at Austin, USA, who investigates superhygroscopic polymers for this purpose, welcomes this new perspective: “The concept of ‘adaptive water harvesting’ is a novel yet powerful engineering approach. It addresses the important aspect of how to maximize practical daily yield of water production for next-generation sorbent materials.”

- Environmentally adaptive MOF-based device enables continuous self-optimizing atmospheric water harvesting,

Husam A. Almassad, Rada I. Abaza, Lama Siwwan, Bassem Al-Maythalony, Kyle E. Cordova,

Nat. Commun. 2022.

https://doi.org/10.1038/s41467-022-32642-0

Also of Interest

- Capturing Water from the Atmosphere,

Roswitha Harrer,

ChemistryViews 2022.

https://doi.org/10.1002/chemv.202200069

Can we harvest drinking water directly from the air around us? – Examples from nature and research