In nature, complex molecules arise from catalytic enzymatic processes that take place in close proximity to one another. The product from one enzyme-catalyzed transformation can be shunted efficiently to the next enzyme without losses due to dispersal or degradation.

One strategy for mimicking this synthetic approach is to incorporate multiple artificial catalysts in one robust structure. Because of their diverse and tunable structures, high surface area, and porous nanoscale channels, metal-organic frameworks (MOFs) are promising both as heterogeneous supports and as hosts for the integration of homogeneous catalysts. However, most MOFs contain only a single type of catalytically active site.

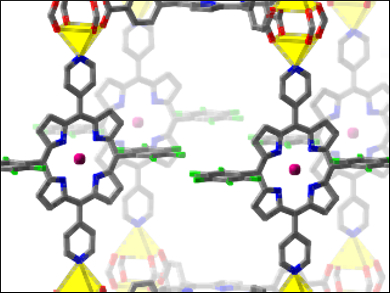

Omar Farha, Joseph T. Hupp, and colleagues, Northwestern University, Evanston, IL, USA, have assembled a MOF containing two types of catalytic species. The team used a stepwise approach such that these catalyst sites are precisely positioned, yet safely isolated from each other in a single architecture. The functional MOF is composed of Robust Porphyrinic Material (RPM) with a pillared-paddlewheel topology. The MOF features Mn porphyrins and Zn porphyrins in an orthogonal arrangement forming large 3D channels (pictured).

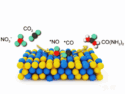

This material can be used to perform a tandem reaction: 1) the Mn porphyrin catalyzes the epoxidation of an olefin substrate and 2) the Zn porphyrin catalyzes epoxide opening and the insertion of CO2. The RPM–MOF was also prepared in a layer-by-layer fashion as a porous and ultrathin film on a self-assembled-monolayer-coated silicon platform. When deployed as a tandem catalyst, the film version displays substantially higher catalytic turnover than that achieved with bulk crystalline MOF samples. This reflects the optimal diffusion of the reactants to the catalyst active sites in the ultrathin film. Catalysts for other tandem reactions should also be accessible by this approach.

- Liquid-Phase Epitaxially Grown Metal-Organic Framework Thin Films for Efficient Tandem Catalysis Through Site-Isolation of Catalytic Centers,

M. Hassan Beyzavi, Nicolaas A. Vermeulen, Kainan Zhang, Monica So, Chung-Wei Kung, Joseph T. Hupp, Omar K. Farha,

ChemPlusChem 2016.

DOI: 10.1002/cplu.201600046This article is part of a special issue of ChemPlusChem on Coordination Polymers and Metal-Organic Frameworks (free to read in August 2016)

Special Issue: Coordination Polymers/MOFs: Structures, Properties and Applications

ChemPlusChem 2016, 81 (8).