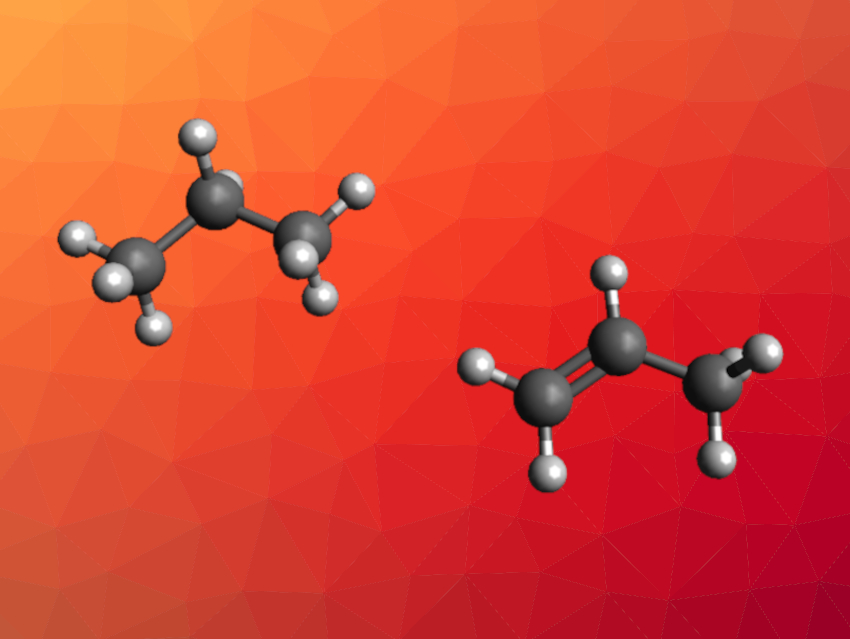

Propane (C3H8) and propene (or propylene, C3H6) are both important industrial chemicals. Separating mixtures of the two formed during production processes is often challenging due to their fairly similar structures. One approach with low energy requirements is physical adsorption. However, this requires tailored materials with ultraporous structures that are well matched to the application to achieve good separation performances. There usually is a trade-off between selectivity and adsorption capacity that makes it difficult to develop optimized high-performance materials. In addition, the materials need to be stable over many cycles for industrial applications.

Guang-Ping Hao, An-Hui Lu, Dalian University of Technology, China, and colleagues have developed ultrathin porous carbon nanoplates (CNPs) for C3H6/C3H8 separation. The team first prepared polymer nanoplates (PNPs) via a kinetics-controlled self-assembly approach from a solution of phloroglucinol and terephthalaldehyde. The PNPs were then carbonized at 1000 °C to obtain CNPs. The resulting nanoplates have a thickness of about 8 nm and sizes of ca. 6 µm by 1 µm. They feature ultramicropores with a narrow size distribution.

The ultrathin shape of the CNPs provides good accessibility of the pores, and the pore sizes are close to the sizes of propane and propylene molecules. It also allows for fast gas transport. The team found a selectivity for C3H6/C3H8 of up to 25, higher than several available adsorbent benchmarks. In addition, the material has a high adsorption capacity and is stable even in the presence of moisture.

- Beyond the Selectivity-Capacity Trade-Off: Ultrathin Carbon Nanoplates with Easily Accessible Ultramicropores for High-Efficiency Propylene/Propane Separation,

Shuang Xu, Wen-Cui Li, Chengtong Wang, Rushuai Liu, Guang-Ping Hao, An-Hui Lu,

Nano Lett. 2022.

https://doi.org/10.1021/acs.nanolett.2c01930