In essence, process safety is about two things, namely,

- preventing acute releases of energy or substances in harmful quantities, and

- limiting the magnitude and consequences of such acute releases should they occur.

Process Safety Management

Process hazards are always present whenever hazardous materials (flammables, toxics, corrosives, biohazards, eco-hazards, etc.) and hazardous processing conditions (temperatures, pressures, flow rates, manual operations, etc.) are present. Organizations in the process industries manage the integrity of their hazardous processes by implementing process safety management systems. In principle, these systems blend engineering, science, and management skills to prevent low-frequency high-severity incidents like explosions, fires, and toxic releases (chemical, bio, eco).

In practice, process safety management systems focus on three key aspects, known as ‘the 3 Ps’:

- Plant – hardware and equipment, e.g., vessels, pipes, pumps, process control instrumentation, etc.

- Process – systems and procedures, e.g., equipment maintenance systems, batch production procedures, training systems, supervision, communication, staffing levels, etc.

- People – how people interact with the plant and the process.

As such, many working within the process industries may not be sufficiently aware of:

- the extent to which process safety informs their daily activities,

- the extent to which their own daily actions influence the standard of process safety in their organizations, and

- the truly catastrophic consequences that can result when too many weaknesses are allowed to develop within their process safety management systems.

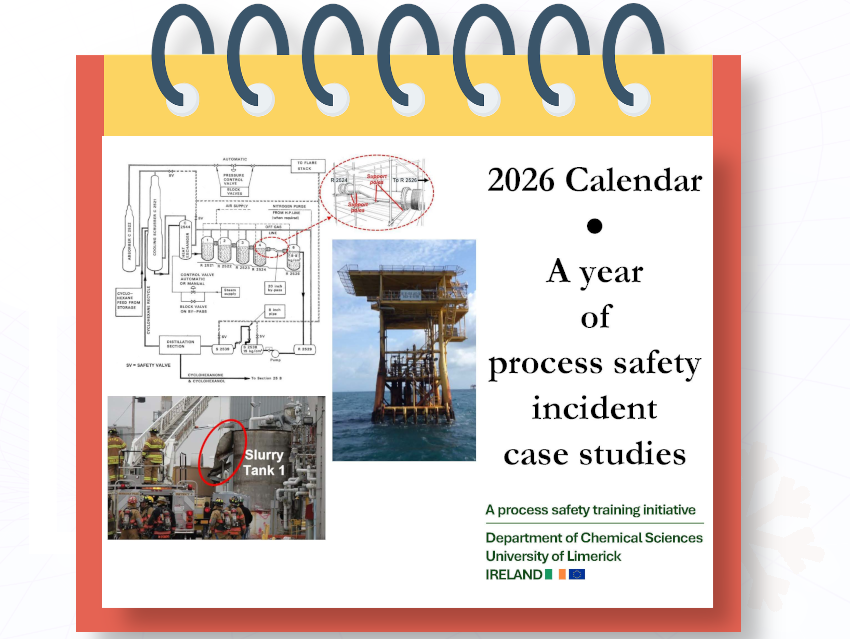

The Calendar

In light of this, Peter Davern (a lecturer in the Department of Chemical Sciences, University of Limerick, Ireland) has created a 2026 Calendar of Process Safety Incident Case Studies (PDF file) as a recurrent, i.e., monthly, learning opportunity in process safety awareness for anyone who hangs up the calendar at their desk, or on the noticeboard in their shared office workspace, break room, control room, maintenance workshop, boardroom, or corner office.

Each month describes in English a different process safety incident, which can be translated as needed using online translator services. Some incidents are well-known, like Bhopal (December) and Seveso (July), while others are less so, like West Pharmaceutical (January) and Fieldwood Energy (May). But all highlight the importance of ever striving to control and contain process hazards. And beyond the descriptions, the contributing factors and the lessons learned, forget not those who were needlessly killed and injured in the calendar’s 12 process safety incident case studies.

➔ Download the PDF and print out the calendar:

Also of Interest

Consequences of electrostatic discharges

Flammable hydrogen-air mixtures

Incompatible mixtures in storage tanks

Hazardousness of high oxygen concentration