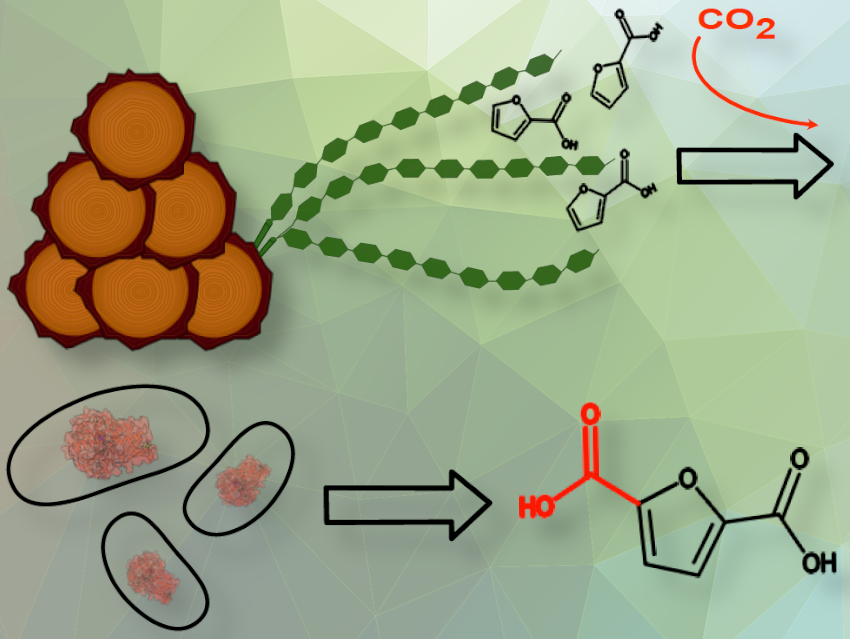

2,5-Furandicarboxylic acid (FDCA) has gained great industrial interest as a renewable alternative to terephthalic acid (TPA) in the generation of bioplastics. Polycondensation of FDCA produces renewable polyesters that can be bio-degradable due to their hydrolysable ester bonds. At the same time, they offer industrially appealing properties (e.g. glass transition temperature) due to their aliphatic backbones. However, while FDCA is considered to be a key platform biochemical, its current chemical production from sugars involves harsh chemistry, which does not align with the 12 principles of green chemistry.

Per-Olof Syrén and colleagues, KTH Royal Institute of Technology, Sweden, have engineered a microbe that efficiently generates FDCA from C5-derived 2-furoic acid and CO2 under ambient reaction conditions. They supplemented Escherichia coli with an exogenous (de)carboxylase enzyme. By using the bacterial cell as a protective chassis, the researchers protect the sensitive and essential co-factor of the enzyme required for enzymatic activity against light-induced inactivation, while still allowing for high conversions.

The team demonstrated the production of high-molecular weight polyesters through the enzymatic co-polymerization of biocatalytically produced FDCA with a renewable diol as a proof-of-concept. The reaction is catalyzed by Candida antarctica lipase B (CALB). The cell factory was compatible with furan-derivatives, accepted high substrate loadings, and eliminated the cumbersome glucose-fructose isomerization step required when starting from C6-sugars.

Currently, the non-circular fossil-based plastics economy is associated with pollution, accumulation of plastic waste, and the release of greenhouse gases such as CO2. According to the researchers, this work emphasizes the potential to use underutilized hemicellulose-derived C5 building blocks to make renewable platform chemicals and materials in a biocatalytic CO2 sequestration process.

- Whole‐cell Mediated Carboxylation of 2‐Furoic Acid Towards the Production of Renewable Platform Chemicals and Biomaterials,

Ximena Lopez-Lorenzo, Heba Asem, Arne Stamm, Sathiyaraj Subramaniyan, Minna Hakkarainen, Per-Olof Syrén,

ChemCatChem 2023.

https://doi.org/10.1002/cctc.202201483