The reduction of friction between moving metal parts in, e.g., a car engine leads to higher fuel economy, lowers CO2 emissions, and reduces long-term engine wear. The addition of oil-soluble polymers to engine oils can have benefits. In addition, core-crosslinked acrylic diblock copolymer nanoparticles have been found to reduce friction. However, the acrylic nanoparticles were prepared by a multi-step process and are not well-suited to industrial scale-up.

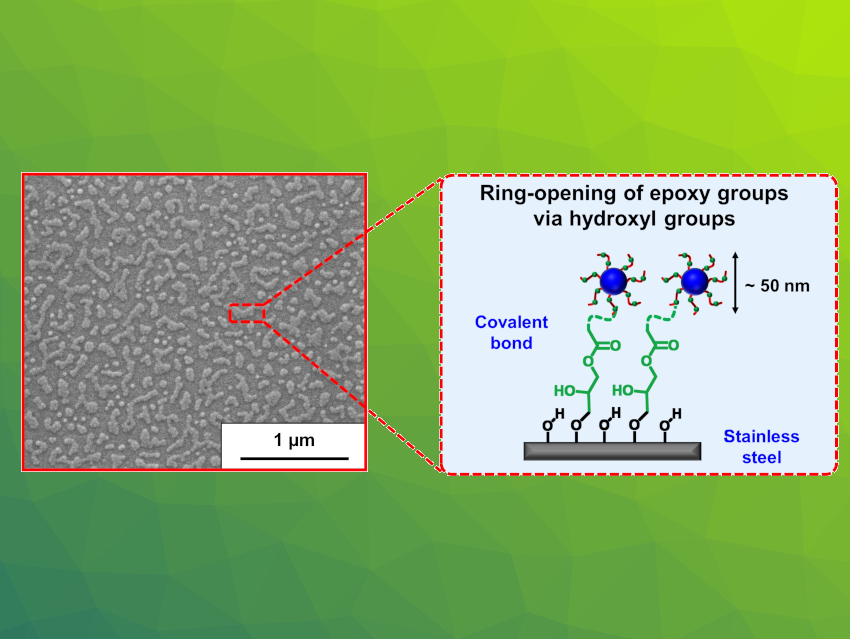

Steven P. Armes, University of Sheffield, UK, and colleagues have designed epoxy-functionalized diblock copolymer nanoparticles that adsorb strongly onto stainless steel to reduce friction. The nanoparticles are readily prepared directly in mineral oil via a combination of reversible addition-fragmentation chain transfer (RAFT) polymerization with polymerization-induced self-assembly (PISA). The team used a statistical copolymerization of glycidyl methacrylate (GlyMA) with lauryl methacrylate (LMA) to prepare a precursor block, followed by chain extension using either methyl methacrylate (MMA) or benzyl methacrylate (BzMA). They obtained spherical nanoparticles with diameters of ca. 27 nm.

The team found that the epoxy groups are critical for enhanced adsorption, most likely because they can react with the stainless-steel surface. For stainless-steel surfaces coated with such nanoparticles, tribological experiments indicated a significant reduction in friction above 90 °C, which corresponds to the typical operating temperature of an internal combustion engine. Control experiments conducted using nanoparticles that contained no epoxy groups led to higher friction. This work could provide useful insights for the rational design of next-generation automotive engine oils.

- Enhanced Adsorption of Epoxy‐Functional Nanoparticles onto Stainless Steel Significantly Reduces Friction in Tribological Studies,

Steven Peter Armes, Csilla Gyorgy, Timothy Smith, David J Growney, Paul Kirkman, Megan Williams, Derek Chan, Thomas Neal,

Angew. Chem. Int. Ed. 2023.

https://doi.org/10.1002/anie.202218397

![Synthesis of [c2]Daisy Chains via Mechanochemistry](https://www.chemistryviews.org/wp-content/uploads/2025/04/202504_RotaxanesWithSolidStateMechanochemistry-125x94.png)