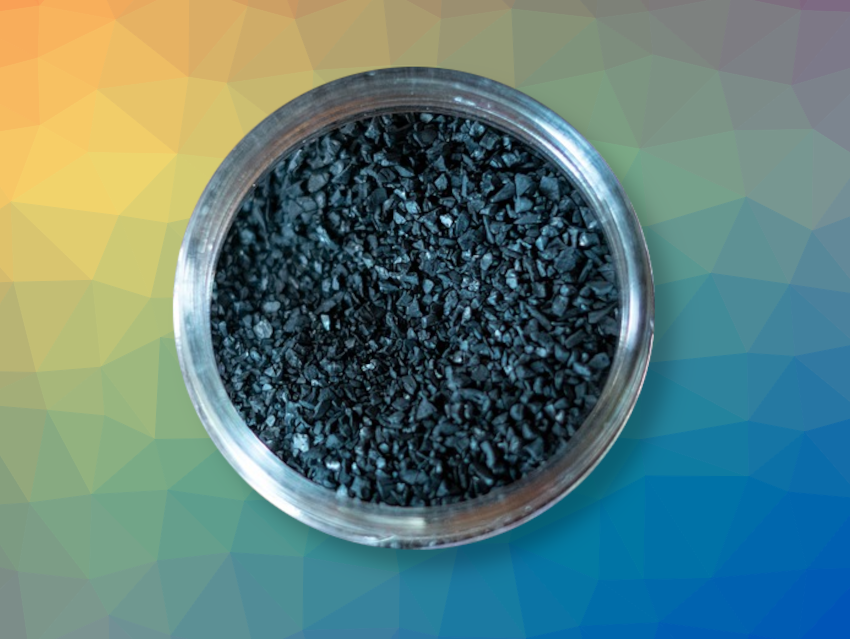

Powdered activated carbon (PAC) plays an important role in drinking water purification and wastewater treatment due to its large adsorption capacity, high specific surface area, nontoxicity, and acid/base resistance. It serves as an efficient adsorbent to remove organic pollutants from water. However, existing PAC regeneration technologies can suffer from high costs, and alternative approaches would be useful.

Zhiyi Lu, Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, Ningbo, Zhejiang, China, University of the Chinese Academy of Sciences, Beijing, and colleagues have developed a cost-effective strategy to regenerate commercially available PAC by anchoring isolated Fe atoms on its surface. The Fe sites enable fast H2O2 activation to produce reactive oxygen species for highly efficient regeneration at room temperature. The team synthesized Fe-PAC with a tunable iron content (0.5–10 %) via a simple pyrolysis strategy. They used a solution of Fe(NO3)3·9H2O and urea in ethanol, which was mixed with a suspension of PAC in ethanol. The precipitate was then heated to 800 °C under a nitrogen atmosphere.

The regeneration and reuse of PAC then involve the separation of spent PAC after water treatment, the regeneration in an H2O2 solution, and the reuse of the regenerated PAC. Using the dye rhodamine B as a representative pollutant, the results of cyclic adsorption-regeneration experiments show that the absorption capability of the synthesized Fe-PAC can be regenerated over ten cycles within 24 h. Compared with traditional regeneration technology, the synthesized Fe-PAC has a relatively low cost, shows higher regeneration efficiency and a lower loss rate of absorbent, and needs a lower H2O2 dosage. The work shows the useful role of atomic dispersion sites in PAC regeneration.

- Cost‐Effective H2O2‐Regeneration of Powdered Activated Carbon by Isolated Fe Sites,

Xu Chen, Ziqi Tian, Qihao Yang, Linjuan Zhang, Qiu Yang, Liang Chen, Zhiyi Lu,

Adv. Science 2022.

https://doi.org/10.1002/advs.202204079

![Synthesis of [c2]Daisy Chains via Mechanochemistry](https://www.chemistryviews.org/wp-content/uploads/2025/04/202504_RotaxanesWithSolidStateMechanochemistry-125x94.png)