Designer MOFs

Swapping out the metals in metal-organic framework materials (MOFs) is one fundamental way in which chemists can tune their characteristics for particular applications. However, while we say “tune”, MOF design is still very much a fine art with a lot of trial and error involved. There is no simple way to predict the synthetic outcome of a given substitution, whether in changing the metal ions or the organic linking units that space those metals apart and give the material its three-dimensional lattice structure.

In the hope of making MOF design and production more rational – for applications in gas storage, separation science, sensors technology, catalysis, and even energy conversion – Dermot O’Hare, University of Oxford, UK, and colleagues have turned to in situ X-ray powder diffraction to help them study the solvothermal formation of a particular group of MOFs, the paddlewheel MOFs based on isostructural M2(bdc)2dabco (M = Zn, Co, Ni; bdc = 1,4-benzenedicarboxylic acid; dabco = 1,4-diazabicyclo[2.2.2]octane). The technique allows the researchers to probe structure in real time.

Pores for Thought

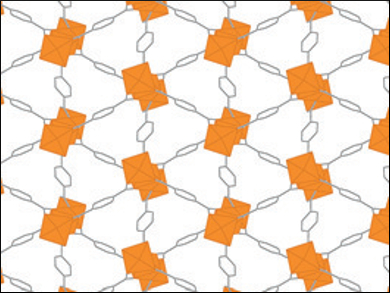

MOFs are a relatively recent discovery. They are crystalline three-dimensional materials formed from a regular network of metal ions interlinked by organic molecules. The organic groups act as spacers to keep the metal ions apart, giving rise to permanent porosity within the solid. These pores can adsorb a wide range of small molecules, often with a useful degree of specificity.

Materials scientists have been searching for new MOFs by combining different metal ions with various classes of organic compounds to create new types of catalyst for the chemical, pharmaceutical, and agrochemicals industries and beyond. Other MOFs can selectively absorb one type of chemical and so could be used to separate different compounds from one another, acting as molecular sieves. Yet other types of MOF might be used to store explosives, fuel, or gases in a safe environment, or even sequester carbon dioxide and other pollutants from exhausts to reduce greenhouse gas emissions.

The porous nature of the MOF lattices gives them a very large internal surface area to volume ratio, with the largest MOF surface areas reaching 5,000 m2/g. Often, novel MOFs turn out to be rather susceptible to degradation. Swapping the organic groups to improve stability alters structures so significantly that the original target application then becomes essentially inaccessible. While looking for alternative organic building blocks for MOFs can be fruitful, using a different metal is an important route to designer materials.

Versatile Lability

Through their X-ray work, O’Hare and his colleagues have demonstrated that the metal ion strongly influences both the kinetics and the intermediates observed in MOF synthesis. They point out that in some instances, multiple intermediates can be formed en route to a target MOF, giving rise to very complex reaction profiles. Additionally, the intermediate phases themselves may be desirable in some cases. This leads to the frustrating conclusion that the traditional models used for understanding materials crystallization are not always applicable to MOFs.

However, the work has also led to the insight that a simple kinetic model can be used to describe their data and so offers a new perspective on phase selection in MOF synthesis, which could assist in the design and construction of MOFs with particular properties. The team explains that the formation kinetics correspond to the degree of chemical lability of the metal ion used in their MOFs (Zn > Co > Ni).

“Versatility in metal ion substitution is a key selling point of MOF chemistry, as different metal ions may impart dramatically different functional properties in frameworks of the same topology, while maintaining desirable structural features,” the team writes in Angewandte Chemie. The model now needs to be further refined so that the relationship between the metal ion and the kinetics for the formation of different MOFs can be modeled in greater detail and allow researchers to take another step towards designer MOFs.

- Time-Resolved In Situ X-ray Diffraction Reveals Metal-Dependent Metal-Organic Framework Formation,

Yue Wu, Sebastian Henke, Gregor Kieslich, Inke Schwedler, Miaosen Yang, Duncan A. X. Fraser, Dermot O’Hare,

Angew. Chem. Int. Ed. 2016, 55, 14081–14084.

DOI: 10.1002/anie.201608463