Heterogeneous catalysts provide several advantages compared to homogeneous catalysts, such as the simple separation of the catalyst from the reaction mixture. Gold nanoparticles (AuNPs) gain increasing attention in the field of catalysis. However, NP aggregation, and, hence, a loss of surface area, is a problem. Moreover, AuNPs can only be reused if they can be efficiently separated from the reaction mixture after the catalysis.

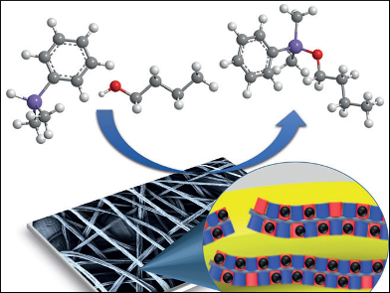

Holger Schmalz, Andreas Greiner, University of Bayreuth, Germany, and colleagues have used a combination of bottom-up (crystallization-driven self-assembly) and top-down (coaxial electrospinning) methods for the preparation of surface-compartmentalized (patchy) nonwoven fabrics. The fibers have a polystyrene (PS) carrier material and were turned into a nonwoven fabric by coaxial electrospinning. The patches on the fiber surface consist of a diisopropylamino-functionalized polystyrene-block-polyethylene-block-poly(methyl methacrylate) copolymer. They were produced using crystallization-driven self-assembly (CDSA). The nanometer-sized patches were then selectively decorated with gold nanoparticles (AuNPs).

The resulting hybrid nonwovens showed excellent stability against AuNP aggregation and were used as a reusable heterogeneous catalyst for the alcoholysis of dimethylphenylsilane without loss of catalytic activity and full conversion over ten reaction cycles. This system could have a broad applicability in catalysis because the patchy hybrid nonwovens can be tailored for the use of different nanoparticles and support materials.

- Bottom-Up Meets Top-Down: Patchy Hybrid Nonwovens as an Efficient Catalysis Platform,

Judith Schöbel, Matthias Burgard, Christian Hils, Roland Dersch, Martin Dulle, Kirsten Volk, Matthias Karg, Andreas Greiner, Holger Schmalz,

Angew. Chem. Int. Ed. 2016.

DOI: 10.1002/anie.201609819