Membranes with Micropores

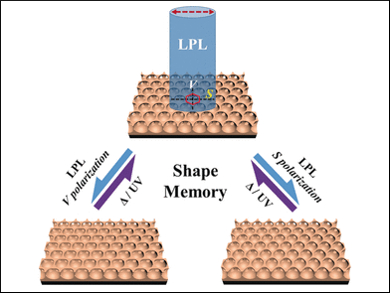

Whether for separation processes, photovoltaics, catalysis, or electronics, porous polymer membranes are needed in many fields. Membranes with micropores that switch between different shapes and/or sizes would expand the possibilities. Zhiqun Lin, Georgia Institute of Technology, Atlanta, USA, Shaoliang Lin, East China University of Science and Technology, Shanghai, and colleagues have introduced a process that produces porous films made from shape memory polymers with precise dimensions. The shape and size of the pores can be reversibly changed with light. No mechanical deformation is needed.

The researchers developed an unconventional strategy to prepare photoswitchable, porous films. Their success stems from a simple method based on condensation patterns known as breath figures. Breath figures are formed when water vapor condenses as a pattern of tiny droplets on a cold solid or liquid surface, like when you breathe onto a cold window. The team used this effect to fabricate a block copolymer film with highly ordered honeycomb pores.

Photoswitching Changes Pore Shape

One block of the polymer network has photoresponsive side-chains with azobenzene units that change their conformation (cis–trans isomerization) in reaction to light. The other block can be crosslinked to fix the configuration of the film. Irradiation with UV light or heating changes a part of the azobenzene units to the bent cis form, irradiation with visible light causes the groups to preferentially adopt the straight trans form. If the visible light is linearly polarized, the side chains arrange themselves in parallel. This rearrangement causes displacement of the material. Careful control of the direction of polarization allows the researchers to transform the originally round micropores into a variety of different shapes, such as rounded rectangles, or rounded rhombuses.

Irradiation with UV light or heating removes the order of the side chains, returning the pores to their original shape or size. The pores can be switched repeatedly. In addition, the copolymer film can also be firstly photoconfigured to a determined pore shape, and then crosslinked to obtain a photoswitchable film with different initial pore shapes. The researchers hope to use their new production method to make robust, switchable films for electronics, photonics, efficient separation and purification processes, and functional biomaterials for regenerative therapies.

- Light-Driven Shape-Memory Porous Films with Precisely Controlled Dimensions,

Wei Wang, Dingfeng Shen, Xiao Li, Yuan Yao, Jiaping Lin, Aurelia Wang, Jiwoo Yu, Zhong Lin Wang, Suck Won Hong, Zhiqun Lin, Shaoliang Lin,

Angew. Chem. Int. Ed. 2018.

https://doi.org/10.1002/anie.201712100