Carbon fibers are often used as a structural reinforcing agent for polymers. These materials are lightweight, and can, for example, help to decrease the CO2 emissions of transport vehicles. One problem in these reinforced polymers is the adhesion between the polymer and the carbon fibers. Poor interfacial adhesion can lead to mechanical failure.

John E. Moses, La Trobe Institute for Molecular Science, Melbourne, Australia, Luke C. Henderson, Deakin University, Waurn Ponds, Australia, and colleagues have developed a way to modify the surface of carbon fibers using a sulfur(VI) Fluoride Exchange (SuFEx) approach [1]. SuFEx uses reactants with –SO2F groups. The –SO2F groups undergo a “click” reaction in which the fluoride is replaced by a nucleophile.

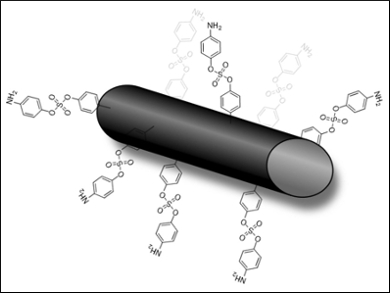

The team first installed sulfur(VI) fluoride units on the surface of the carbon fibers, either via electrochemical deposition of an aryldiazonium salt with a fluorosulfate moiety or by treating the material with SO2F2. A 4‐aminophenol silyl ether was used as nucleophile then used to functionalize the surface (result pictured).

The attachment of the aromatic amine to the fiber surface increased the adhesion between the fiber and an epoxy resin by 130 % relative to an unfunctionalized control. The mechanical strength of the fibers remained unchanged. According to the researchers, this procedure provides a simple method for tailoring the surface of carbon fibers for different applications.

- Modification of Carbon Fibre Surfaces by Sulfur-Fluoride Exchange Click Chemistry,

James D. Randall, Daniel J. Eyckens, Filip Stojcevski, Paul S. Francis, Egan H. Doeven, Anders J. Barlow, Andrew S. Barrow, Chantelle L. Arnold, John E. Moses, Luke C. Henderson,

ChemPhysChem 2018.

https://doi.org/10.1002/cphc.201800789

[1] Jiajia Dong, Larissa Krasnova, M. G. Finn, K. Barry Sharpless, Sulfur(VI) Fluoride Exchange (SuFEx): Another Good Reaction for Click Chemistry, Angew. Chem. Int. Ed. 2014. https://doi.org/10.1002/anie.201309399