The high capacity of silicon makes it a most promising anode material for lithium-ion batteries (LIBs). Various silicon composites have been developed to serve as anodes for LIBs. However, quality requirements and the complex treatment of the reagents hinder the industrial application of silicon anodes.

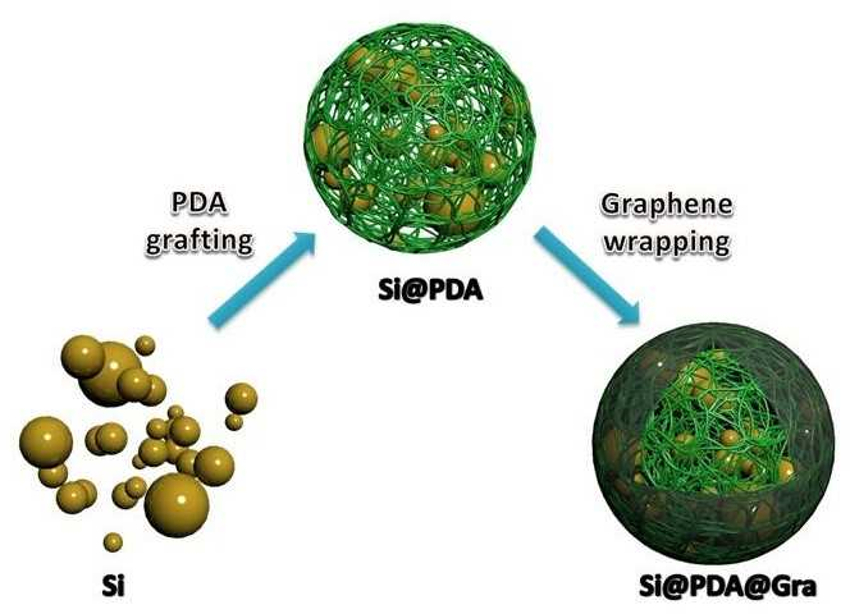

Jinying Zhang, Xi’an Jiaotong University, China, and colleagues have used a simple method to prepare graphene-coated silicon nanoparticles with polydopamine (PDA) buffers (Si@PDA@Gra, pictured) as LIB anodes. The used silicon materials are industrial grade and do not require further treatment. Silicon nanoparticles with different sizes were covered in PDA to assemble micro- to submicro Si@PDA particles by stirring a mixture of Si nanoparticles and dopamine hydrochloride in a buffer solution. The Si@PDA structures were then coated with thin-layered graphene using mechanical methods.

The polydopamine buffer layer provides space to expand for the silicon nanoparticles during the charging and discharging process. The graphene coating keeps the silicon particles together without disintegration and improves the electrical conductivity of the nanoparticles. A capacity of 1100 mAhg–1 was achieved by the Si@PDA@Gra anodes after 550 cycles at a current rate of 200 mAg–1. This method provides anode materials that can be made from industrially available silicon.

- A Facile Path to Graphene-Wrapped Polydopamine-Entwined Silicon Nanoparticles with High Electrochemical Performance,

Zechen Liu, Jialiang Huang, Xuewen Zhao, Hongyang Huang, Chengcheng Fu, Zhihui Li, Yonghong Cheng, Chunming Niu, Jinying Zhang,

ChemPlusChem 2019, 84, 203–209.

https://doi.org/10.1002/cplu.201800554