Cup-shaped particles combine an anisotropic shape with an open cavity useful for capture, transport, and release of cargo. In order to direct the uptake of cargo exclusively to the inside of the cup when facing different environments, it would be desirable to give such cups a Janus character, i.e., surfaces with different chemical properties inside and outside.

André H. Gröschel and colleagues, University of Duisburg-Essen, Duisburg, Germany, have developed a method to fabricate Janus nanocups by combining evaporation-induced confinement assembly (EICA) with ABC triblock terpolymers. The team used polystyrene‐block‐polybutadiene‐block‐poly(tert‐butyl methacrylate) (SBT).

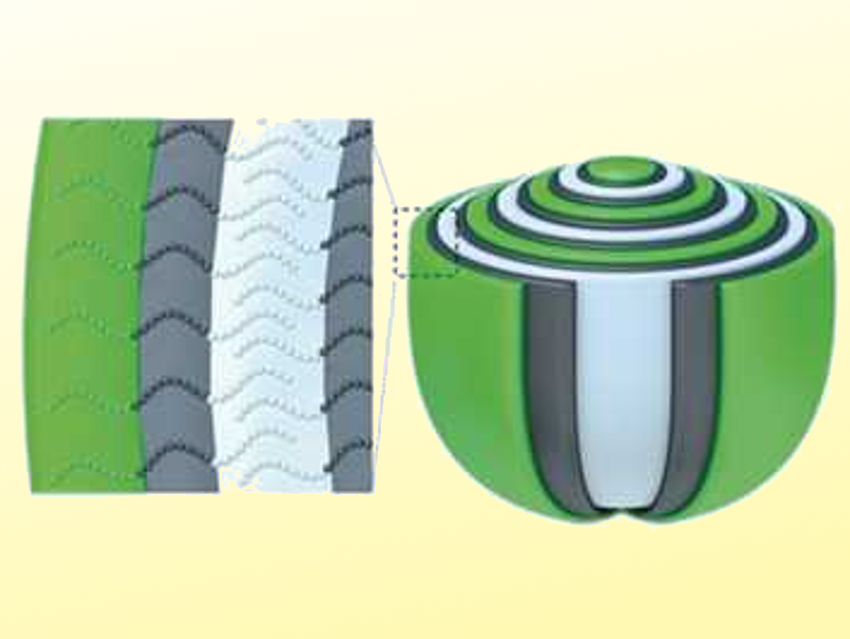

First, “tulip-bulb” microparticles (pictured) are formed by the polymers in the confinement of nanoemulsions. After cross-linking the polybutadiene middle block and redispersion in a good solvent, the microparticles disassemble into cup-shaped nanoparticles with attoliter volume, nanoscale wall thickness, and different chemistry on the in- and outside.

The mechanical stability of these Janus nanocups, which controls opening and closing of the cavity, was tuned synthetically by varying the polymer block lengths. Due to the Janus character, cargo could be stored in the interior with high selectivity. This approach provides a template- and additive-free route towards Janus nanocups which may have applications, e.g., in oil-spill recovery.

- Template-Free Synthesis and Selective Filling of Janus Nanocups,

Xiaolian Qiang, Andrea Steinhaus, Chen Chen, Ramzi Chakroun, André H. Gröschel,

Angew. Chem. Int. Ed. 2019.

https://doi.org/10.1002/anie.201814014