In a series of interviews and articles experts and speakers at the BASF Science Symposium “Smart Energy for a Sustainable Future” outline the importance of new energy technologies and materials innovations. Professor Ekkes Brück, Delft University, Fundamental Aspects of Materials and Energy research group, The Neherlands, is one of the speakers of the Smart Energy Symposium. Here he tells the story of magnetocaloric cooling.

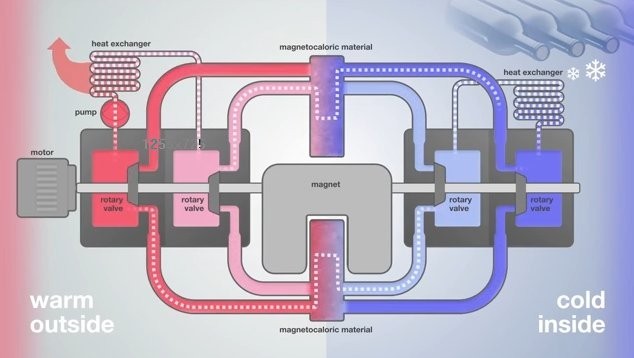

Magnetocaloric materials heat up when put in a magnetic field and cool down when removed from the magnetic field. In the magnetocaloric heat pump, the magnetocaloric materials go in and out of the magnetic field and at the same time heat is transferred from the cold interior of the wine cooler to the warm surrounding air by circulating a water-based coolant through the magnetocaloric materials.

Screenshot was taken from following video: https://www.youtube.com/watch?feature=player_embedded&v=jnl9m0rSE7U&x-yt-ts=1421914688&x-yt-cl=84503534

Professor Brück, how does magnetocaloric technology relate to good wine?

The effect that magnetocaloric materials change temperature under an applied magnetic field has been known for more than 90 years. But only lately we have started to explore its potential for applications in energy-efficient, gas-free refrigeration. So when our team together with BASF researchers started thinking about a prototype, we did a lot of brainstorming on suitable applications. One meeting continued late into the evening and over a glass of wine – and the rest is history! We agreed that a wine cooler would be a great demonstrator to show how the heat pump works, how it competes with other technologies, and which are environmental advantages. And at the beginning of this year, after several years of research, we have unveiled the first prototype!

What inspired you in the beginning to this research?

The starting point for my research was a paper on magnetic phase transitions of a gadolinium–silicon–germanium material, which showed a combined structural and magnetic phase transition and therefore had a larger magnetocaloric effect than pure gadolinium [1].

To use magnetocaloric materials in commercial applications near room temperature such as in standard kitchen equipment, rare-earth materials such as gadolinium are too expensive. You will never be competitive with anything like the compressors used today.The paper gave me the idea of using this phase-transition trick on manganese alloys. Manganese has quite reasonable magnetic moments. Research finally led me to the manganese–iron–phosphor–silicon material that is now used in the refrigerant prototype.

Refrigeration systems based on the magnetocaloric effect can be up to 35 % more energy-efficient than the current vapor compression systems. Are there more reasons why magnetocaloric materials could lead in the smart use of energy in the cooling industry?

I never made the full calculation, but when you build a compressor for a refrigerator, you have involved a lot of materials and with the current technology you produce greenhouse gases.

The greenhouse-gas output from the cooling industry is expected to rise to almost a quarter of the total greenhouse-gas production, if nothing changes. Magnetocaloric machines use solid, nontoxic materials and have no greenhouse-gas effect. Moreover, recycling on an almost element-specific basis is extremely simple by using a magnet and different temperatures. This reduces the impact on the environment significantly.

Will this revolutionize our refrigeration technology?

There are still a few things to solve before you really have the ideal competitor to current refrigerator compressors. It is not a coincidence that the technology was used in a special refrigerator for the very first time. This wine-cooler is a product for the high-end market, where customers are less concerned with the price of the heat pump and willing to pay for latest technology.

It is still a bit early to really become competitive for a broad market. We still need strong magnets, which makes the equipment a little expensive. However, we are now working on further improving the materials and are developing new materials that can also work at lower magnetic fields. So instead of 1 Tesla we can then work with ½ Tesla.

Are there other alternative cooling technologies to the status quo?

Two technologies come to mind. First: For the last 150 years, people have been looking for good thermoelectric materials [2]. This is a very elegant method, because you only need a current to cool. However, as you transport heat you generate heat, because a current always produces Joule heating. This has made these devices rather inefficient to date and I do not really see any developments that get close to the efficiency of the current compressors. We actually expect that the magnetocaloric devices will be more efficient than the current compressors, so I can’t really see thermoelectric competing here.

The second: In principle, solid-state refrigeration is also possible with electrocaloric or barocaloric materials [3]. Here you would have a similar machine to that for magnetocaloric cooling, but the material would be subjected to an electric or pressure field. Up to now, all the demonstrated barocaloric and electrocaloric effects have been much lower than what is achieved with magnetocaloric materials. Therefore, I don’t see too much competition here either.

What fascinates you about magnetocaloric materials?

In the case of the manganese–iron–phosphor–silicon materials we now have an example of a material in which you really have a change of the magnetic moment and the bonding at the same time.

We have two requirements: a high critical temperature and a large magnetocaloric effect. To achieve this, manganese and iron have separate roles. The manganese atoms with well-defined magnetic moments and strong exchange interactions secures the critical temperature near room temperature. On the other hand, we need to have a massive entropy change, which in our case comes from iron, which completely changes its electronic state. In the ferromagnetic state iron d-electrons are used for bonding; in the paramagnetic state they carry a magnetic moment and cannot bond. We get an electronic phase transition without a volume change, which is kind of special. For industrial applications this is very useful because you do not want the material to change volume too much in the cycle.

There is a lot of physics and chemistry in these materials which surprises us again and again.

Thank youf for the interview.

What do you think – how will magnetocaloric materials allow a smart use of energy?

References

[1] D. Haskel, Y. B. Lee, B. N. Harmon, Z. Islam, J. C. Lang, G. Srajer, Ya. Mudryk, K. A. Gschneidner, Jr., V. K. Pecharsky, Role of Ge in Bridging Ferromagnetism in the Giant Magnetocaloric Gd5(Ge1-xSix)4 Alloys, Phys. Rev. Lett. 2007, 98, 247205. https://doi.org/ 10.1103/PhysRevLett.98.247205

[2] Joseph R. Sootsman, Duck Young Chung, Mercouri G. Kanatzidis, New and Old Concepts in Thermoelectric Materials, Angew. Chem. Int. Ed. 2009. https://doi.org/10.1002/anie.200900598

[3] Lluís Mañosa, Antoni Planes, Mehmet Acet, Advanced materials for solid-state refrigeration, J. Mater. Chem. A 2013, 1, 4925–4936. https://doi.org/10.1039/C3TA01289A

Related Articles

- Nguyen H. Dung, Zhi Qiang Ou, Luana Caron, Lian Zhang, Dinh T. Cam Thanh, Gilles A. de Wijs, Rob A. de Groot, K. H. Jürgen Buschow, Ekkes Brück, Mixed Magnetism for Refrigeration and Energy Conversion, Adv. Energy Mater. 2011, 1 (6), 1215–1219. https://doi.org/10.1002/aenm.201100252

- F. Guillou, G. Porcari, H. Yibole, N. van Dijk, E. Bruck, Taming the First-Order Transition in Giant Magnetocaloric Materials, Adv. Mater. 2014, 26 (17), 2671–2675. https://doi.org/10.1002/adma.201304788

- X. F. Miao, L. Caron, P. Roy, N. H. Dung, L. Zhang, W. A. Kockelmann, R. A. de Groot, N. H. van Dijk, E. Brück, Tuning the phase transition in transition-metal-based magnetocaloric compounds, Phys. Rew. B 2014, 89 (17), 174429. https://doi.org/10.1103/PhysRevB.89.174429

- F. Guillou, H. Yibole, G. Porcari, L. Zhang, N. H. van Dijk, E. Brück, Magnetocaloric effect, cyclability and coefficient of refrigerant performance in the MnFe(P, Si, B) system, J. Appl. Phys. 2014, 116 (6), 063903. https://doi.org/10.1063/1.4892406

- H. Yibole, F. Guillou, L. Zhang, N. H. van Dijk, E. Bruck, Direct measurement of the magnetocaloric effect in MnFe(P,X) (X = As, Ge, Si) materials, J. Phys. D: Appl. Phys. 2014, 47 (7), 075002. https://doi.org/10.1088/0022-3727/47/7/075002