The European Commission has estimated that in Europe only 12 % of secondary materials and resources are returned to the current economy. This means that this economy is still largely linear [1]. A Circular Economy Action Plan has been adopted in March 2020 and should boost circular economy projects at the levels of research, development, marketing, and consumers. This plan is part of the European Green Deal.

There is a great number of definitions for the term “circular economy” [2]. Recently, Anke Weidenkaff told ChemistryViews that the aim of a circular economy is to make it a closed product cycle by re-use, recycling, refurbishment, or regeneration of all used materials [3]. More globally, we often contrast it with the linear economy (“make, use, dispose”), ![]() emphasizing the need to set up closed loops for materials while reducing the consumption of virgin resources and the resulting negative effects on the environment. The circular economy should not be restrictive and should allow the emergence of new opportunities and innovations. The circular economy leads to an increase in the value of resources by increasing their conversion into higher-value products while eliminating low-value waste. Moreover, the lifetime of products is increased. In terms of waste valorization, we all have waste from the manufacturing industry in mind, but waste from nature can also be affected by these new circular economy loops, as some examples in this article will show.

emphasizing the need to set up closed loops for materials while reducing the consumption of virgin resources and the resulting negative effects on the environment. The circular economy should not be restrictive and should allow the emergence of new opportunities and innovations. The circular economy leads to an increase in the value of resources by increasing their conversion into higher-value products while eliminating low-value waste. Moreover, the lifetime of products is increased. In terms of waste valorization, we all have waste from the manufacturing industry in mind, but waste from nature can also be affected by these new circular economy loops, as some examples in this article will show.

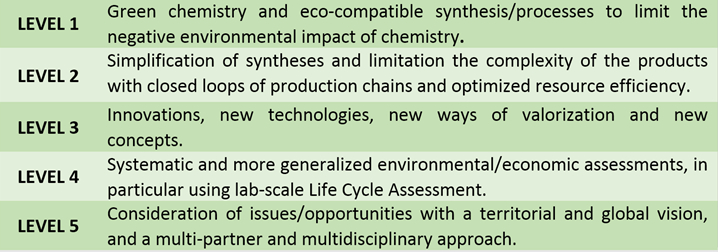

Five Levels of Contribution of Chemistry to a Circular Economy

In a concept article recently published in Chemistry – A European Journal, I discussed how chemistry can contribute to the circular economy approach to improve our environmental, economic, and societal system [4]. Through five proposed levels of contribution (see Fig. 1), chemists can take their part in this adventure:

- innovation through the consideration of green chemistry principles,

- the simplification of syntheses,

- development of new technological systems and novel ways of valorization,

- systematic and generalized environmental and economic assessment,

- global approach in link with other actors and disciplines.

This last level encourages chemists to work together even more closely across all fields of chemistry to find complementary solutions, but also to contribute more broadly by adopting territorial, multi-partners, and multidisciplinary approaches within circular economy projects to ensure positive overall impacts.

|

|

Figure 1. The five levels of contribution of chemistry to a circular economy [4]. |

In conclusion, the circular economy is a huge opportunity to innovate and work differently, but it is also a great need for our planet, and especially for the planet that we will leave to our children and their descendants. Indeed, we cannot over-consume resources which no longer have time to renew themselves or which become missing. Earth Overshoot Day, the calculated illustrative calendar date on which humanity’s resource consumption for the year exceeds Earth’s capacity to regenerate those resources that year, occurs earlier every year (August 22nd in 2020). In addition, as David Cole-Hamilton, University of St. Andrews, UK, and EuChemS President from 2014 to 2017, rightly pointed out recently, if we fail to build a sustainable world, economy, poverty, inequality, economic stagnation, and conflict will all grow towards the destruction of the world as we know it [5].

How to Start a Circular Economy in a Territory

One interesting point is how to start a circular economy in a territory. For example, if there is no collection of a waste type, it is impossible to valorize it, but if there is no valorization, a collection has no reason to exist. The starting point of these new projects of circular economy are often an opportunity, a meeting of actors, people who want to work together, etc. However, these opportunities have to be provoked. Below are three examples where we created new projects of circular economy thanks to these particular conditions.

First Example: Opportunities from a Chance Encounter

In 2016, a colleague told me—over a coffee—how she was fighting against the invasion of Japanese Knotweed (Fallopia japonica) on her personal land. Indeed, this invasive alien plant is a large clump-forming plant, which grows up to 3 m tall, with light-green, shield-shaped leaves and bamboo-like, hollowed stems. It spreads very quickly and can invade an entire surface thanks to its thick and extensive roots called rhizomes, which can reach several meters deep (see Fig. 2).

The main problem is its strong spread: A few millimeters of rhizomes can allow Japanese Knotweed to grow, preventing any other plant species from developing. In addition to the problem of biodiversity loss it poses, Japanese Knotweed leads to economic losses in land values as well as roadside safety problems. Because of its very efficient mode of propagation, the waste resulting from the mowing or uprooting of this invasive plant is no longer accepted in municipal waste disposal centers.

|

|

Figure 2. Japanese Knotweed. |

We started to work on the valorization of the rhizomes in the lab, through the extraction of molecules with a great potential for cosmetic and nutraceutical applications. A bit by chance, we met an executive employee from a chemical industry company who wanted at this moment to create a start-up to find an environmental sense in his professional action. Some years later, after obtaining funding from various sources and the work of several interns and postdoctoral fellows, a patent had been filed and the start-up Rhizomex had been created [6]. Indeed, our eco-friendly process allows the grinding, extraction, in-situ transformation, and purification of some selected polyphenols of interest from the rhizomes (see Fig. 3).

Then, the start-up was developed to create a rhizomes recovery channel while offering a new valorization outlet, with a territorial approach. The proposed solution is a double valorization through the extraction of molecules of interests as well as an agronomic valorization of the solid extraction residue—leading to a zero-waste circular economy strategy.

|

|

Figure 3. The exciting approach of this research was to start from the grubbing-up site and follow through to the lab, working on large amounts of rhizomes. |

Second Example: Opportunities from a Network

I am involved in a network of eco-industries in the Savoie territory (French department), where research laboratories and companies regularly meet to bring about new projects on waste and, more generally, on the circular economy. We started a project in 2017 with a local company in this network, Trialp, that collected used frying oils and coffee grounds from the restaurants of the territory. In our lab, we started to valorize coffee grounds, in particular, using supercritical fluids.

|

|

Figure 4. Our first visit to the Trialp facilities in 2017. |

Another avenue of innovation that a circular economy can bring is the functional economy, where customers pay for the use of products and not for their possession. In this case, the paradigm shift lies in the fact that the product is no longer sold (and then does not become a waste produced by the customer), but it remains the property of the company that operates it. The customer uses it and then the company can ensure its recovery, recyclability, and traceability much more easily.

By collecting ground coffee, Trialp has noticed that the majority of the restaurants are supplied with coffee by the same company. We could imagine an original system where this company will not sell coffee but rather propose a “coffee service”, recovering the coffee grounds after its use in the restaurant. Thus, the recovery of the coffee grounds will be facilitated, as well as its recycling, while maintaining the traceability and tracking of the products. In conclusion, it could be interesting to explore this approach in the framework of circular economy.

Third Example: A New Regulation Leading to the Need to Change Practices

In December 2017, a prefectural order was taken to prohibit the burning of agricultural waste in the open air in the Savoie Mont Blanc territory (France). In this context, we started to work with the winegrowers, the state and environmental services, the city representatives, the political decision-makers, the associations, the citizens, and several other researchers to develop alternatives to the burning of viticultural waste (see Fig. 5), produced annually across the territory.

We formed the consortium over nearly a year to convince all the actors to join us and participate in this territorial project. We also had to quickly find funding solutions to start and launch the research project—which we called VITIVALO—with my colleague Dr. Piot, with whom I coordinate this project [7]. The development of a cascade of valorization ways, rather than a single valorization path, proved necessary to set up a viable economic sector on the territory and achieve acceptable environmental standards.

|

|

Figure 5. The viticultural waste studied in the VITIVALO project. |

Indeed, we showed that molecules of interest can be extracted from grapecanes and grapevine stocks [8]. In particular, the most widespread grapevine varieties in the Savoie Mont Blanc territory, the Jacquère and Mondeuse varieties, contain promising amounts of two stilbenes, trans-resveratrol (Rsv) and trans-ε-viniferin (Vf), compared with the well-known high stilbene levels in the Gewurztraminer and Pinot Noir varieties [9]. In these studies, we also highlighted the great variability of the extracts’ composition as a function of the applied pre-extraction parameters in the lab.

The VITIVALO project also involves several laboratories and companies working on the impact on air quality and the valorization of extraction residues as insulating bio-based materials or for industrial compost. This strategy of a cascade of valorization ways aims to propose a zero-waste approach. The establishment of comparative Life Cycle Analyses (LCA) is also planned to assess the set-up of this new sector on the territory. Finally, we communicate with inhabitants, citizens, and especially with several primary schools (see Fig. 6) to sensitize the students and their families to the developed approach.

|

|

Figure 6. Through the “One Year with VITIVALO” program, several schools worked on these issues and informed the families of the territory. |

In summary, the chemists learned a lot from the understanding of the practices and issues of viticulture professionals thanks to this broader approach of the VITIVALO project. Indeed, they had been able to bring additional innovations compared to those which might have resulted from a more traditional “chemist’s approach”. For example, we focused our study on the period of cutting of grape canes (November–March) and not on the overall year to focus on real conditions. The grape canes from different vine varieties are often mixed in vineyards, which is why we studied the effects of the varieties—leading to interesting differences. The meteorological conditions (exposure to the sun, amount of rain, etc.) or the cultivated land (type of soil, slopes, etc.) can also lead to interesting discoveries on the content of molecules of interest.

In addition to the waste valorization, other positive effects may result from the implementation of circular economy projects—such as, in our case, the creation of a new local economic sector in a territory, a reduction in the impact on air quality, as well as helping to change the practices in viticulture professions and supporting decision-makers.

This type of project, where waste transport distances have to remain limited to make sense in terms of circular economy and environmental impact, is generally linked to a defined territory. However, an added value may be to serve as an example whose system can be then reproduced in other territories (for example, in other wine regions) and finally lead to global impacts on a larger scale.

New Opportunities and Collaborative Approaches

In many cases, the solutions have to be brought by a combination of expertise and a cascade of approaches, involving all fields of chemistry (organic, engineering, analytical, polymer, and/or inorganic chemistry). However, chemists have also to work more closely with other disciplines (political scientists, economists, ecologists, sociologists, computer scientists, etc.) through multidisciplinary approaches that can lead to exciting synergistic effects and innovations! In the case of the VITIVALO project, for example, the imagined cascade of valorization was possible only by a collaboration between organic chemists, analytical chemists, materials-, and polymer engineers. Atmospheric chemists were also involved to demonstrate the impact of the current practices of open-air burning. Specialists in economy and sociology were also involved to evaluate the economic and societal advantages of developing a new circular economy sector in the territory.

In addition, I really believe that circular economy projects require not only the participation of researchers. They also have to involve all the actors of the studied value chain, including the companies, the consumers, and the decision-makers. All the actors have to be brought together in a consortium for each project, often in a particular territory, and work together. Based on these thoughts, chemists are encouraged to integrate projects of circular economy with a territorial and global vision, and a multi-partner and multidisciplinary approach.

References

[1] European Commission, Press release: Changing how we produce and consume: New Circular Economy Action Plan shows the way to a climate-neutral, competitive economy of empowered consumers, March 11, 2020. (Accessed August 31, 2020)

[2] V. Rizos et al., The Circular Economy: A review of definitions, processes and impacts, CEPS Res. Report 2017, 8, 41.

[3] K. Welter, A. Weidenkaff, Efficient and Sustainable Resource and Cycle Strategies, ChemViews Mag. 2020. https://doi.org/10.1002/chemv.202000001

[4] G. Chatel, Chemists around the World, Take Your Part in the Circular Economy!, Chem. Eur. J. 2020, 26, 9665–9673. https://doi.org/10.1002/chem.202002327

[ 5] D. Cole-Hamilton, The Role of Chemists and Chemical Engineers in a Sustainable World, Chem. Eur. J. 2020, 26, 1894–1899. https://doi.org/10.1002/chem.201905748

[6] G. Chatel et al., Patent FR 20 06171, 2020.

[7] VITIVALO Project, www.vitivalo.univ-smb.fr. (Accessed May 10, 2020)

[8] M. Zwingelstein et al., Viticultural wood waste as a source of polyphenols of interest: Opportunities and perspectives through conventional and emerging extraction methods, Waste Manag. 2020, 102, 782–794. https://doi.org/10.1016/j.wasman.2019.11.034

[9] M. Zwingelstein et al., trans-Resveratrol and trans-ε-Viniferin in Grape Canes and Stocks Originating from Savoie Mont Blanc Vineyard Region: Pre-extraction Parameters for Improved Recovery, ACS Sustainable Chem. Eng. 2019, 9, 8310–8316. https://doi.org/10.1021/acssuschemeng.8b06723

Author

Dr. Gregory CHATEL

Dr. Gregory CHATEL

Univ. Savoie Mont Blanc, LCME, F-73000 Chambéry, France.

E-mail: [email protected]

Orcid: 0000-0001-8814-812X

Twitter: https://twitter.com/gregory_chatel

Gregory Chatel received his Ph.D. from the Université de Grenoble, France, in 2012. Then, he joined Robin D. Rogers’ group at the University of Alabama, Tuscaloosa, USA, as a Postdoctoral Research Fellow. In 2013, he joined the IC2MP Institute of the Université de Poitiers, France, as an Assistant Professor. In 2016, he joined the LCME Laboratory of the Université Savoie Mont Blanc, France, where he performed research in green chemistry and sonochemistry for biomass and waste valorization as well as processes of fine chemistry. He completed his habilitation and became associate professor in 2018.

Today, Gregory Chatel is Co-Leader of the Matter team of the new interdisciplinary EDYTEM Institute (Université Savoie Mont Blanc/CNRS) following the merger of the two laboratories, LCME and EDYTEM (becoming EDYTEM, officially on January 1st, 2021). In 2020, he received the silver medal of the European Young Chemists’ Award from the European Chemical Society (EuChemS).