An environmentally friendly and sustainable synthesis of “heavyweight” polymers with very narrow molecular weight distributions is a useful concept for modern polymer chemistry. Thanks to a new photoenzymatic process, Ruoyu Li, Shanghai University, China, and Zesheng An, Jilin University, Changchun, China, have been able to increase the range of possible monomers. The team obtained well-defined linear and star-shaped polymers with ultrahigh molecular weights.

Precision Polymers

Because many polymer properties depend heavily on molecular weight, it is desirable to have as narrow a molecular weight distribution as possible. Precision polymers with ultrahigh molecular weights (≥ 1 t/mol) would be interesting candidates for high-performance elastomers, low-concentration hydrogels, photonic materials, durable coatings, and flocking agents. However, such heavyweight polymers are not easy to produce with a uniform distribution of molecular weights.

The radical polymerizations in widespread use are especially difficult to control in this respect. Modern methods, such as RAFT (reversible addition–fragmentation chain transfer) polymerization offer a significantly higher degree of control by keeping the concentration of reactive radicals very small. A special agent reacts reversibly with the growing polymer chains to form a nonradical species. Whenever the intermediate dissociates, new active radicals are formed. This slows the reaction and results in longer, more uniform polymer chains.

Photoenzymatic RAFT Polymerization

Ultraheavy polymers with narrow weight distributions were previously only attainable from conjugated monomers. It has never been possible to make such polymers from nonconjugated polymers whose vinyl group (-CH=CH2) is bound directly to a noncarbon atom.

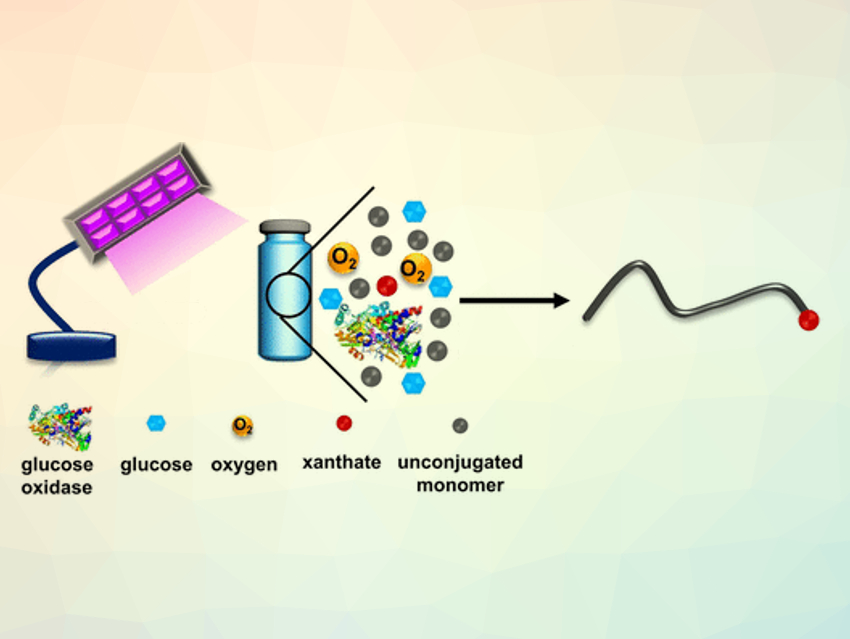

The researchers have overcome this challenge with a simple, environmentally friendly RAFT polymerization that is based on enzymatic photocatalysis. The enzyme glucose oxidase (GOx) oxidizes glucose with oxygen, reducing the flavin-containing cofactor FAD to FADH−. The latter acts as a photocatalyst when irradiated with visible light, starting the radical chain reaction. GOx consumes the oxygen present in the solution—another advantage because oxygen disrupts conventional radical polymerizations and must be removed beforehand. The chain propagation agents the team uses are xanthates (sulfur-containing carboxylic acid derivatives).

The researchers attained well-defined linear and star-shaped polymers in nearly quantitative yield, as well as various copolymers with previously unattainable uniform ultrahigh molecular weights, starting from nonconjugated monomers. The reaction, which offers outstanding control over composition, molecular weight, and architecture is simple to carry out and takes place under mild conditions (10 °C) in water.

- Achieving Ultrahigh Molecular Weights with Diverse Architectures for Unconjugated Monomers through Oxygen‐Tolerant Photoenzymatic RAFT Polymerization,

Ruoyu Li, Zesheng An,

Angew. Chem. Int. Ed. 2020.

https://doi.org/10.1002/anie.202010722