Environmentally friendly photonic pigments are useful colorants and could replace traditional dyes or pigments in some applications. Self‐assembly is important for creating such photonic structures. Their structural color is tunable, but this is usually based on differently sized building blocks obtained by time‐consuming chemical synthesis.

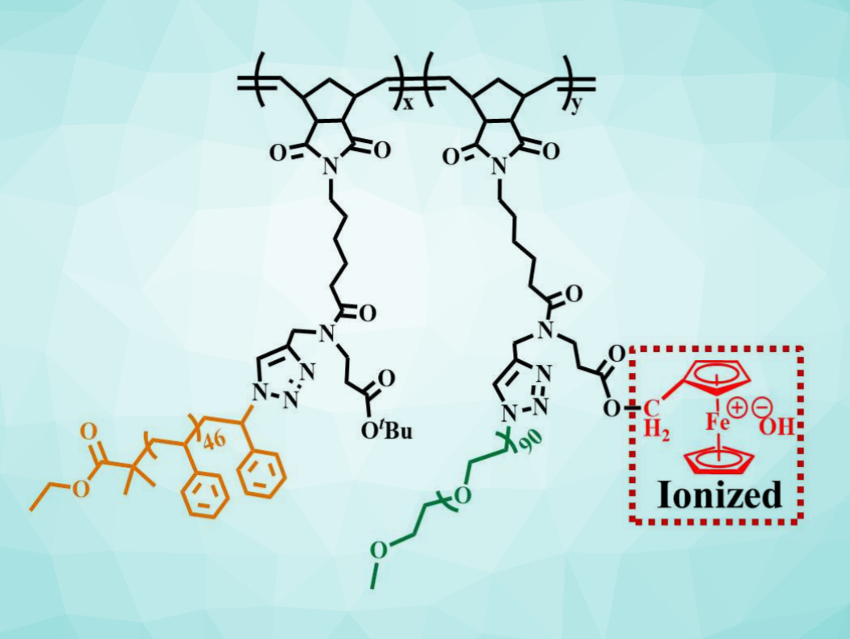

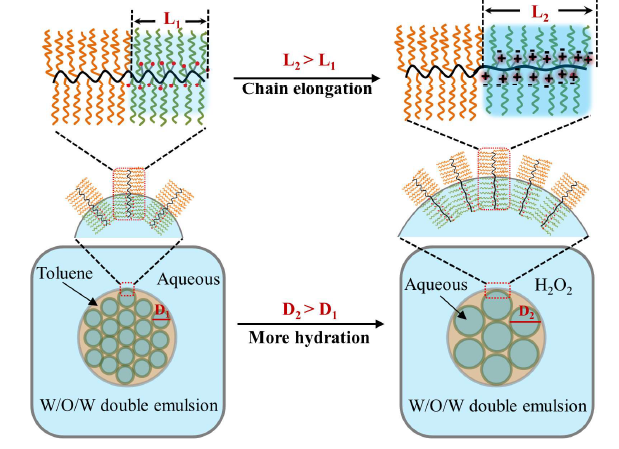

In order to overcome this challenge, Dong-Po Song, Tianjin University, China, and colleagues have developed a new method for the production of full-spectrum photonic pigments. They used bottlebrush block copolymers (BBCPs) with oxidation-responsive ferrocene units (pictured above) as a single building block. The researchers obtained porous particles by drying ordered water-in-oil-in-water (W/O/W) double emulsions stabilized by the polymer, which acts as a surfactant (pictured below). The lattice spacing of the photonic structures was tuned by controlling the polymer chain stretching via an oxidation reaction. The oxidation of the ferrocene groups by hydrogen peroxide leads to enhanced hydrophilicity, more hydration, and chain extension. This larger extension leads to a longer wavelength of reflected light.

The strategy is simple but powerful for the scalable production of porous materials. These materials may be useful not only for photonic applications, but also for energy storage and conversion, drug delivery, catalysis, or separation.

- Oxidation Control of Bottlebrush Molecular Conformation for Producing Libraries of Photonic Structures,

Yu-Lian Li, Xi Chen, Hong-Kun Geng, Yun Dong, Bin Wang, Zhe Ma, Li Pan, Gui-Qiu Ma, Dong-Po Song, Yue-Sheng Li,

Angew. Chem. Int. Ed. 2020.

https://doi.org/10.1002/anie.202011702