Materials scientists often look to the natural world for inspiration, for example, in the colorful iridescence of feathers and the wings of butterflies, but also in the hard and shiny realm of pearls and nacre.

Mimicking Biology

Finding inspiration is one thing, but finding a way to mimic biology is another. Nature has had millions of years to hone its skills in generating substances and structures to solve almost every adaptation problem and to fill every evolutionary niche. As such, there is a complexity that has arisen through natural selection that cannot always be easily replicated in the lab when biomimetic materials are synthesized.

With nature handling the synthetic procedures on our behalf, we cultivate the most suitable types of trees to give us particular types of wood for a given application, we use yeasts and fungi to process resources into substances such as soy sauce or alcohol. We are even learning how to brew up alternatives to animal proteins that have some of the structural integrity of meat, but without the environmental and ethical problems of rearing animals for slaughter.

Using Living Cells to Grow Biomimetic Materials

Qiming Wang, University of Southern California, Los Angeles, USA, and colleagues have brought these two realms together: mimicking nature, but also using nature to do the making. The researchers have investigated how they might harness the synthetic and structure-building prowess of living cells to grow biomimetic materials that have ordered microstructures. They turned to living bacteria and 3D printing to grow bionic mineralized composites. The specific strength and fracture toughness of the resulting materials are, the team reports, comparable with natural composites. These materials also have an exceptional capacity for energy absorption that is superior to both their natural and synthetic counterparts.

The synthesis of such hybrid materials had previously been hampered by a lack of control of the mineral orientation. The researchers suggest that their work could lead the way to a new type of hybrid synthetic–living materials with exceptional properties that have stiff mineral components and soft organic constituents.

Mineralization within 3D-Printed Polymer Scaffolds

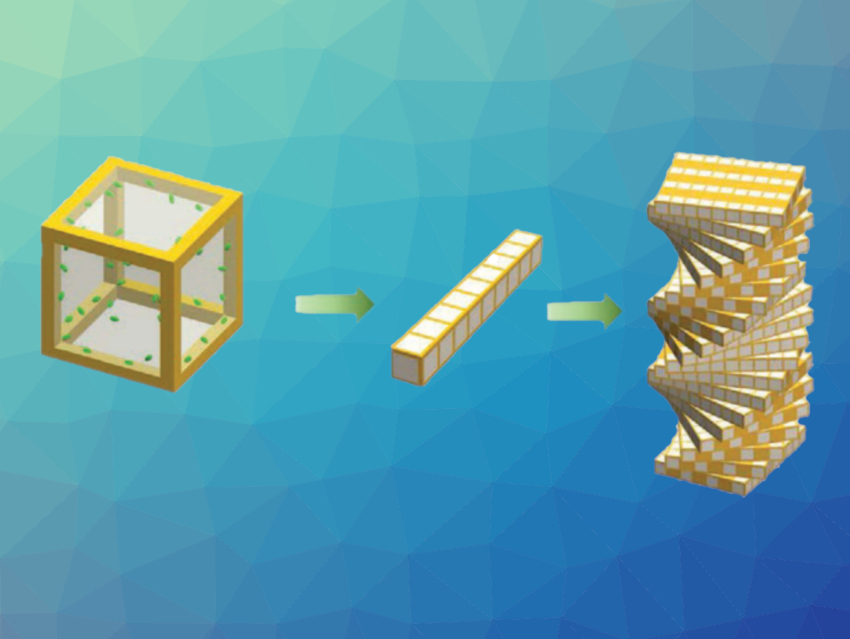

The work builds on the way in which certain sea creatures, such as mussels, use β-chitin as a protein scaffold on which they build a mineral structure. The team made a 3D-printed polymer scaffold as a surrogate for the natural β-chitin matrix. They then applied Sporosarcina pasteurii bacteria to the polymer surface to act as nucleation sites for mineralization. The bacteria-coated polymer scaffold is bathed in a solution of urea and calcium. The enzyme urease is secreted by the bacteria, which decomposes the urea to carbonate. This generates calcium carbonate, which then forms deposits of calcite on the polymer scaffold, nucleating at the bacterial centers and growing to fill the voids.

If only urease is used in the absence of the bacteria, the process fails, i.e., the bacteria are a key component of the developed approach. These experiments, the researchers suggest, represent the first time bacterial mineralization has been harnessed to guide the formation of designed structural composites. “The manufacturing strategy can be easily extended by selectively controlling the activity of living organisms to synthesize unprecedented structural composites with ordered, hierarchical, and gradient microstructures,” the team concludes.

- Growing Living Composites with Ordered Microstructures and Exceptional Mechanical Properties,

An Xin, Yipin Su, Shengwei Feng, Minliang Yan, Kunhao Yu, Zhangzhengrong Feng, Kyung Hoon Lee, Lizhi Sun, Qiming Wang,

Adv. Mater. 2021.

https://doi.org/10.1002/adma.202006946