Metal–organic framework (MOF) membranes have a variety of potential applications, including chemical sensing, separation, catalysis, and the development of sophisticated nanodevices. Thus, convenient, low-cost, and universal techniques for their preparation are essential. The most widely used strategy to construct MOF membranes uses metal–ligand coordination bonding interactions between the MOF membrane and the substrate. To date, all methods are limited to specific MOFs and surface-functionalized substrates. This constrains the application of these methods and results in high costs. In 2010, the first free-standing MOF platelets were reported, but few studies into the assembly of large-scale, smooth, and free-standing MOF membranes have emerged so far.

S. L. Qui and colleagues, Jilin University, China, have developed the first polymer-supported method to prepare intergrown and free-standing MOF membranes. This MOF membrane fabrication method is simple and convenient and can be applied to a variety of material compositions to produce functional membranes with diverse micropore structures, opening up a host of opportunities for the development of new functional nanodevices.

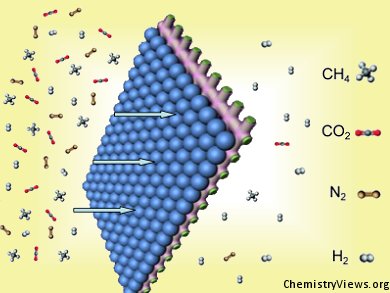

By using this method, they have fabricated a stainless-steel-net/poly(methylmethacrylate)–poly(methacrylic acid)-supported HKUST-1 (a copper-based MOF) membrane that can be used for gas separation. The results indicate that this type of membrane has a high separation factor for H2/N2, H2/CH4, and H2/CO2 gas mixtures.

Image: © Wiley-VCH

- Polymer-Supported and Free-Standing Metal–Organic Framework Membrane,

T. Ben, C. Lu, C. Pei, S. Xu, S. Qiu,

Chem. Eur. J. 2012.

DOI: 10.1002/chem.201201574