New lithium-ion battery (LIB) materials are needed that have a high specific capacity and remain stable after many charge/discharge cycles. Researchers have found that nanoscale materials can better accommodate the volume changes that occur during lithium insertion and extraction, leading to enhanced cycling performance.

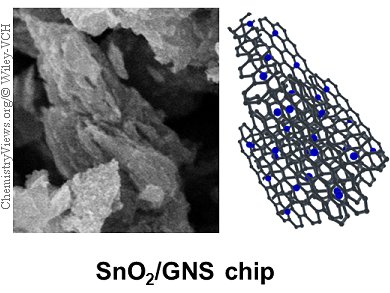

Zhongping Shao and colleagues, Nanjing University of Technology, China, have developed a simple yet effective ball-milling route to generate SnO2/graphene nanocomposites for LIB anodes. This method uses relatively cheap starting materials, Sn powder and graphite oxide, and transforms them into a composite made up of approximately 4 nm SnO2 nanocrystals and 3–5 layer graphene through a redox reaction initiated by grinding.

When these nanocomposites were used in LIBs, a high specific capacity of 891 mA h g–1 could be achieved, even after 50 cycles at 100 mA g–1. This result is much better than that obtained with a composite electrode composed of commercially available SnO2 nanoparticles and reduced graphene, which degraded rapidly.

- Facile Mechanochemical Synthesis of Nano SnO2/Graphene Composite from Coarse Metallic Sn and Graphite Oxide: An Outstanding Anode Material for Lithium-Ion Batteries,

Fei Ye, Bote Zhao, Ran Ran, Zongping Shao,

Chem. Eur. J. 2014.

DOI: 10.1002/chem.201304720