Simple Separation Process for Neodymium and Dysprosium

Rare-earth metals are critical components of electronic materials and permanent magnets. Recycling of consumer products is a promising source for these rare commodities. In the journal Angewandte Chemie, American scientists have now introduced a simple method for separating mixtures of neodymium and dysprosium salts – an important step towards recycling these valuable rare-earth metals.

The rare-earth elements are a group of metals that are present in rare minerals. When isolated, they were obtained as oxides, which at the time were referred to as “earths”. Some of the rare-earth metals have interesting properties and are used in electronic components and magnets.

Rare, yet Important Metals

The strongest permanent magnets made to date, for example, are “neo magnets” made from a neodymium-iron-boron alloy, which may also contain other rare-earth metals such as praseodymium, terbium, and especially dysprosium. Neo magnets are used in loudspeakers and headphones, motors of rechargeable tools, read and write heads of hard drives, and in the electrical generators used in wind turbines.

Today, many of these rare-earth metals have supply problems because their deposits are usually small and extraction and purification are difficult. Because of their technological importance and supply problems, the United States Department of Energy has classified dysprosium and neodymium as “critical materials”.

Recycling Magnets

One possible source of these materials is actually at hand: recycling used magnets. So far, however, only a very low percentage of the metals have been obtained from recycling – as mixtures. Because the concentrations of the individual rare-earth metals can vary, they must be separated before reuse. However, this is difficult, energy- and time-intensive, and requires large amounts of solvent.

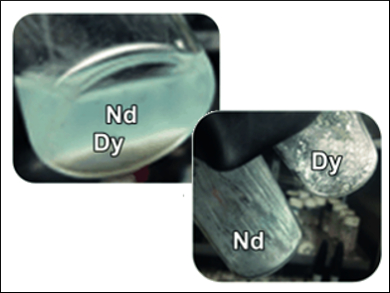

A team headed by Eric J. Schelter, University of Pennsylvania, Philadelphia, PA, USA, has now developed a simple and effective method for separating neodymium and dysprosium from each other. In this process, a special nitroxide ligand is added to simple salts of the metals. This ligand is an organic molecule that grasps an individual metal ion in a coordination complex like a clamp with three “arms”. If the bound metal ions have a large radius, like neodymium, pairs of these complexes prefer to form a dimer. In contrast, complexes with small metal ions like dysprosium barely form any dimers at all. As a result, the neodymium complex is fifty times more soluble in benzene than the dysprosium complex.

With a minimal amount of benzene, the researchers were able to leach the neodymium complex out of a 1:1 mixture in about 95 % purity. The solid left behind contained about 95 % of the dysprosium complex. It is possible to increase the purity of both fractions after further purification steps with benzene.

It should be possible to apply this technique to other rare-earth elements. This simple, cost-effective method could make the recycling of rare earths more attractive in the future.

- An Operationally Simple Method for Separating the Rare-Earth Elements Neodymium and Dysprosium,

Justin A. Bogart, Connor A. Lippincott, Patrick J. Carroll, Eric J. Schelter,

Angew. Chem. Int. Ed. 2015.

DOI: 10.1002/anie.201501659