Catalysts for Water Splitting

Electrocatalytic water splitting is one of the most promising next generation technologies for environmentally friendly and inexpensive energy conversion and storage. However, one of its biggest obstacles is the sluggishness of the oxidation reaction, which is key to the whole process. State-of-the-art technology relies on metal oxide electrocatalysts, but both cost and performance still need to be improved.

In the journal Angewandte Chemie, Chinese scientists have now introduced oxidized, that is, rusty, stainless-steel plates as excellent electrocatalysts for oxygen evolution. That technology could represent a surprisingly simple approach toward solving a long-standing problem.

Sluggish Oxidation

The water splitting reaction represents the conversion of water into oxygen and hydrogen. Although this principle used in plants is the most important energy converting reaction on Earth, it is difficult to implement as industrial processes. One of the key challenges is the development of suitable catalysts to accelerate the sluggish oxidation reaction of water for the generation of oxygen.

The requirements for possible electrocatalysts are manifold, including durability and low cost. The best electrocatalysts considered today are the oxides of the heavy metals ruthenium and iridium, but they are expensive and scarce, whereas the cheaper ones based on earth-abundant transition metals need other improvements. In an unusual approach, Xinbo Zhang, Chinese Academy of Sciences, Changchun, and colleagues have turned a simple stainless steel plate electrode into a highly efficient electrocatalyst just by artificially corroding its surface.

Turning Steel to Rust on Purpose

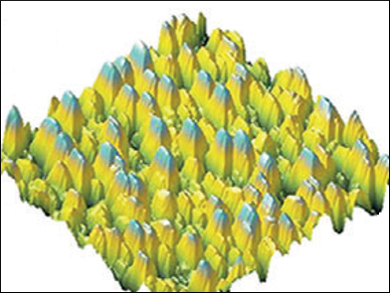

This planned corrosion includes hydrothermal and electrochemical treatment in alkaline solution, and it renders the formerly smooth and plain surface brownish-rusty. Rusty, but perfect for catalysis, as especially nickel hydroxides, released from the steel, are known to be excellent electrocatalysts. And second, as the scientists point out, the rougher and more basic surface is perfectly wettable, it provides excellent contact to the current collector, and is stable and robust.

Neither long-term stability nor the necessary reactivation of the active surface seem to be problematic. The reactivation can be carried out by the same process used for introducing the artificial corrosion. Alluding to the low reputation of “rust” as seemingly deteriorated material, the scientists say their method is “turning waste into treasure”. Their approach was shown to be practical, efficient, and could be a very promising start for next generation water splitting technologies.

- In Situ Activating Ubiquitous Rust towards Low-Cost, Efficient, Free-Standing, and Recoverable Oxygen Evolution Electrodes,

Haixia Zhong, Jun Wang, Fanlu Meng, Xinbo Zhang,

Angew. Chem. Int. Ed. 2016.

DOI: 10.1002/anie.201604040