Zeolites with micropores provide unique catalyst activity but lead to slow mass transfer of reactants and products. A hierarchical pore network would allow fast mass transfer from the surface of the zeolite crystal through large mesopores, while maintaining the selectivity of micropores.

Krijn de Jong and co-workers, Utrecht University, the Netherlands, have developed a zeolite with three pore sizes: micropores (ca. 1 nm), small mesopores (ca. 3 nm), and large mesopores (ca. 30 nm). They used commercially available zeolite H-Y that had been steamed and acid-leached. Base leaching was performed with NaOH(aq), followed by acid quenching. Subsequently, sodium ions were exchanged for ammonium ions, followed by calcination to obtain the zeolite.

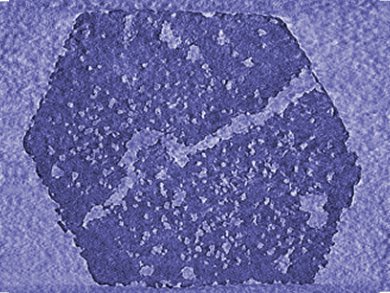

The zeolite was characterized by X-ray diffraction and transmission electron microscopy. It was also shown to be suitable for hydrocracking under industrial conditions. It gave higher conversions to diesel and kerosene and less naphtha than a commercial catalyst.

- Zeolite Y Crystals with Trimodal Porosity as Ideal Hydrocracking Catalysts

K. P. de Jong, J. Zečević, H. Friedrich, P. E. de Jongh, M. Bulut, S. van Donk, R. Kenmogne, A. Finiels, V. Hulea, F. Fajula,

Angew. Chem. Int. Ed. 2010.

DOI: 10.1002/anie.201004360