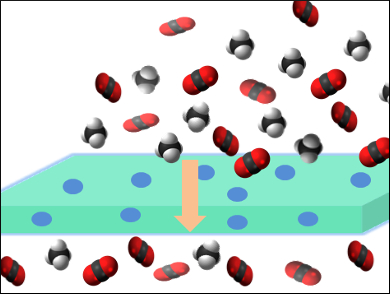

Membrane separation is a promising technique for the removal of CO2 from fuel gas. CO2 can cause pipeline corrosion and decreased heating values. However, with established polymeric membranes, a compromise must be reached between gas permeability and selectivity.

Mixed-matrix membranes (MMMs), which consist of polymeric matrices containing selected fillers, represent a strategy to overcome this limitation. In the past, fillers have included zeolites, nanocarbons, and metal-organic frameworks (MOFs), but these fillers commonly have problems such as poor compatibility, aggregation, and pore blocking.

Beatriz Seoane, Utrecht University, The Netherlands, Jorge Gascon, Delft University of Technology, The Netherlands, and colleagues have developed a new type of MMM consisting of the commercial polymer matrix Matrimid® and a microporous azine-linked covalent organic framework (COF) as filler. COFs are a type of porous organic polymer and have been used in gas sorption, catalysis, sensing, and photovoltaics.

Their incorporation into MMMs afforded more than double the CO2 permeability of bare Matrimid®, alongside slightly improved selectivities. This makes COFs promising candidates for use in gas separation with MMMs.

- Azine-Linked Covalent Organic Framework (COF)-Based Mixed-Matrix Membranes for CO2/CH4 Separation,

Meixia Shan, Beatriz Seoane, Elena Rozhko, Alla Dikhtiarenko, Guillaume Clet, Freek Kapteijn, Jorge Gascon,

Chem. Eur. J. 2016.

DOI: 10.1002/chem.201602999